When special manufacturing turns out to be the solution

At JIOrings, as in life, standard stuff is sometimes no longer worth it. When it happens that we cannot fulfill our client’s needs with any of our pieces from our large stock, it is necessary to create a special piece.

This kind of piece based on a drawing or sample is manufactured for a specific client and must meet some specific requirements. We design and develop pieces of specific manufacturing according to our client’s needs. Thanks to our experience and our partners (recognized laboratories and national and international factories) we can successfully tackle with great challenges.

The manufacturing process of special pieces at JIOrings aims to achieve our clients’ satisfaction. In the first phase, we examine each client’s needs: how the pieces will be like (hardness, compression set, elasticity, resistance), which applications will they have… We design a mold based on a drawing or sample provided by the client and we take into account the specifications of each piece. Once the mold has been made, we manufacture a pre-series which is sent to the client so that they might check it and make all the necessary proofs. In other words, we properly homologate the sample. Once the piece has been approved, we put all hands on deck and we start producing the special pieces that have been asked, without forgetting the deadlines and quantities.

There are many advantages for making special pieces at JIOrings:

- We examine each client’s needs and we offer a measured solution.

- We have more than 14 years experience in the sector.

- We manufacture molds or equipment at very low cost.

- We can produce special pieces in short edition.

- We manufacture pieces that meet required international norms (food, drinking water…).

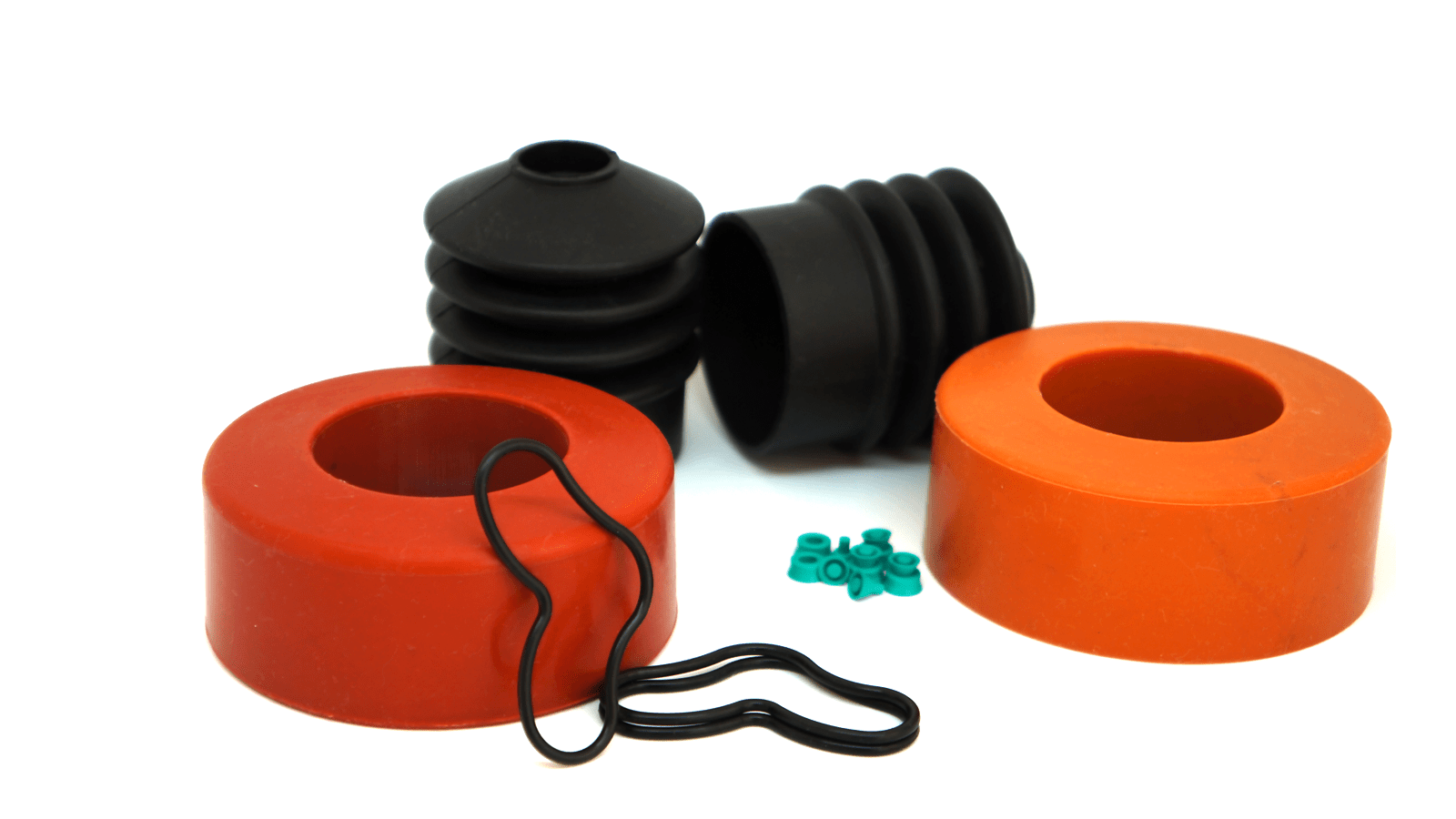

These are some of the lately produced pieces that we have manufactured:

| Part | Material | Features | Description | |

|

Collar | FPM 70 SH A Green |

|

Pumping equipment. |

|

Fuse holder attachment | VMQ 35 SH A Dielectric Red RAL-2001 |

|

A special mixture developed for fuse holders with special insulating features, low residual deflection, and with personalised hardness and colour. |

|

Quad-Ring | EPDM 80 SH A Peroxide Black (4442-N69) for potable water |

|

Included in assembly of pressurised tanks for the treatment of potable water. |

|

Cap | Neopreno 50 SH A Black |

|

Dust caps for compact gas cells. |

|

O-Ring | EPDM 65 SH A |

|

O-ring with a rectangular perimeter for pressure relief in gas cells. |

|

Shaped seal | NBR 70 SH A Black |

|

Sealing parts with a toroid cross-section for fluid control units which measure the oil that is being dispensed at each service point in an automobile repair shop. |