Washers, without mould cost, without minimum order

Washers, square- or rectangular-section rings

We are going to dedicate this post to washers. Until now, we have been focusing on raising awareness of our different lines of seals month by month. We started this series of “one month, one seal” with the most common one of all, the o-ring. But we have also written about seals which, a priori, are not so well known, such as RB gamma seals. We have one of the largest stocks of seals on the peninsula and it is our objective to raise awareness of the products in our catalogue, both seals as well as washers.

Rubber washers are circular components with a hole in the centre. It is a very simple product that we at JIOrings can manufacture in different ways:

- Punched out of a sheet.

- Cut from a tube moulded or extruded.

- Moulded.

Each production system has its advantages and distinctive features. In the case of washers manufactured by punching out of a sheet, we offer these pieces with a maximum diameter of 500 mm, and from a minimum thickness of 0.1 mm, in a range of hardnesses from 30 to 90 on the Shore A scale, and in any rubber (NBR, EPDM, silicone, food-grade silicone, etc.). In the case of washers cut from a tube (moulded or extruded), we can obtain these pieces with square edges, reducing the percentage of defects such as marks, notches, burrs, etc. Moulded washers allow us to offer these pieces suitable for more specific technical requirements (any material, size, colour, certification, etc.) than the other two systems.

The most common applications for these pieces are found in usage situations such as taps, plumbing, ironmongery, etc. although, in reality, we can find a washer anywhere there is a nut or a screw and a need to uniformly distribute the pressure applied by the nut o screw on the surface. We can also use these parts to avoid liquids leaking, ensure sealing, insulate, provide constant support, etc.

These are some of the advantages that parts can provide when used:

- Tight tolerances, particularly as regards thickness.

- Excellent price/quality ratio, particularly for medium-sized and large series.

- Smooth finish of the surface and the edges.

- No investment in moulds for the most standard sizes.

At JIOrings, we offer you a wide range of standard washers as well as made-to-measure moulded washers, washers which meet the need of a particular design, manufacturing tailored to your more specific needs (NO mould cost, NO minimum order). Request your quote or go to our online shop to make your purchase.

Encapsulated O-rings, the solution for harsh environments

The encapsulated O-rings, the seals with an encapsulation that sets it apart

We have decided to give the encapsulated O-rings the importance they have always deserved, creating a specific area with its technical data sheet, 3D photos of the part both whole and in section, and a video of it in movement.

The encapsulated O-ring consist of a core in silicon (VMQ) or fluorocarbon (FPM) which is completely enclosed in a seamless FEP or PFA encapsulation. These seals are the ideal solution in the face of sealing problems given their chemical resistance, elastic properties, and low friction.

The encapsulated seals combine the resilience and sealing typical of elastomers with the chemical resistance of PTFE. Because they are made of a core of VMQ or FPM covered with a thin capsule of the polymers FEP or PFA, the result is a high-performance sealing product.

Because they are resistant to solvents and are chemically inert (except for contact with alkaline metals, fluorine, and some halogen compounds at high temperature), the encapsulated O-rings compensate for some of the limitations of traditional O-ring seals. On the one hand, they provide a level of resilience very similar to that of elastomers. And on the other hand, the extremely low coefficient of friction (0.1 and 0.2) of the polymer FEP allows for a very low permeability to gases. This means that encapsulated O-ring seals are almost universally used in harsh environments.

Due to all of these features, encapsulated O-ring are used above all in applications such as pumps and valves, marine motors, mechanical locking, filters, pneumatic motors, heat exchangers, autoclaves, pipelines, and compressors, among others.

The materials used for the covering of the seal are FEP and PFA, as we mentioned earlier. Their properties are similar although PFA displays better behaviour with temperatures in excess of 200 ºC. For any inquiries, do not hesitate to consult the technical data sheet:

| O-Ring | Profile | Material | Temperature |

| Encapsulated |  |

FPM + FEP | -20 to +205 ºC |

| Encapsulated |  |

VMQ + FEP | -60 to +180 ºC |

The seamless uniform FEP encapsulation provides the seals almost a universal sealing capability whilst the continuous reset and the constant pressure of the encapsulation onto the sealing point is performed by the core. As a result, there is a huge sealing compression that increases with media pressure.

In summary, the following are the main features of encapsulated O-rings:

- They offer a high chemical resistance.

- They function in a wide temperature window.

- They can withstand high-pressure-bearing situations.

- Their surface is low friction and has a low absorption of solvents.

- They enjoy high resistance to “COMPRESSION SET“.

- Their capacity for watertightness exceeds that of other seals.

- They can be described as being similar to an elastomer with a “teflon” coating.

HP Rotary Shaft Seals, the all terrain seals

HP Rotary Shaft Seals, the secret is in the housing

We are continuing our “one month, one seal” initiative. In previous posts we talked about the universal nature of O-rings, cord-ring and its tailor-made cut, quad-rings and their four support points… However, there is still much to say in relation to seals, and this time we are going to address the seal which is capable of withstanding the most adverse conditions: rotary shaft seals, more, specifically, HP (high-pressure) rotary shaft seals.

So what do these deals have that the others don´t? What sets them apart from the rest is their composition. HP rotary shaft seals are composed of an SS304 or SS316 stainless steel housing and a white PTFE FDA or a black PTFE/Fiberglass/MoS2 lip. Moreover, these seals feature a fluoroelastomer (Viton®) reinforcement.

Indeed, HP rotary shaft seals are high-performance rotating seals used in a wide range of sectors such as mechanical engineering and the chemical industry for use in centrifuges, pumps, mixers, compressors and gearboxes. Here are some of the advantages of using this type of seal:

- A reduction in the risk of corrosion due to the housing.

- An excellent seal for use in high temperatures, speeds and/or pressures and with corrosive liquids and gases.

- Efficient in situations of poor lubrication and dry conditions.

These are the characteristics which make HP seals an excellent seal for use in high temperatures, speeds and/or pressures and with corrosive liquids and gases. Furthermore, they work efficiently in cases of poor lubrication and even in dry conditions. If you are in doubt, consult the HP seal technical data sheet:

| Material | Pressure | Temperature | Speed | Video |

| PTFE FDA+INOX304 PTFE/FIBERGLASS/MOS2+INOX304 | ≤25 Bars | -90 to +250 ºC | ≤45 m/s |

And best of all, we are the quickest way to find a seal, whereby you will have your HP seals within a few days if not available fortwith. Place your order with our online store, always available.

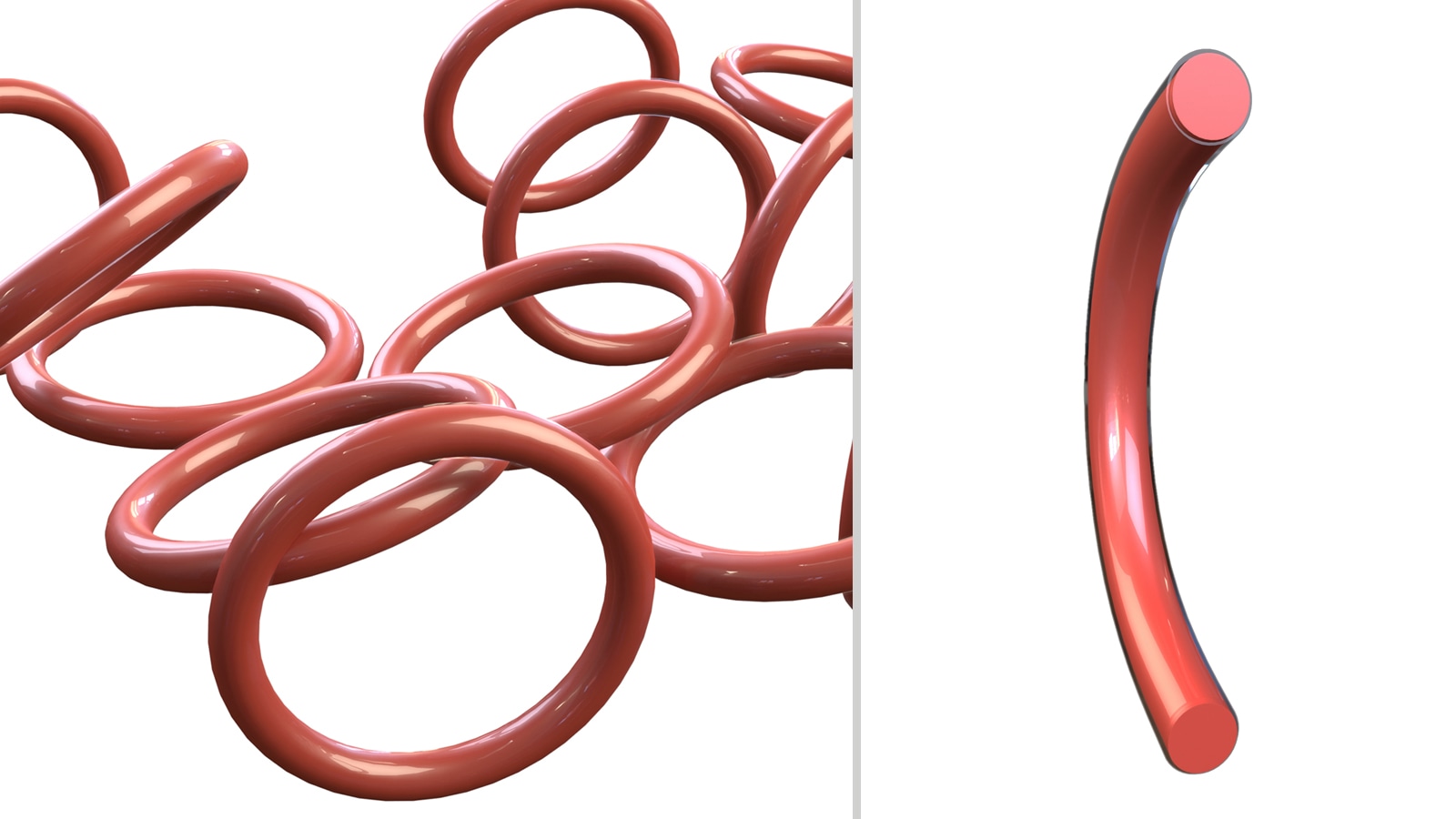

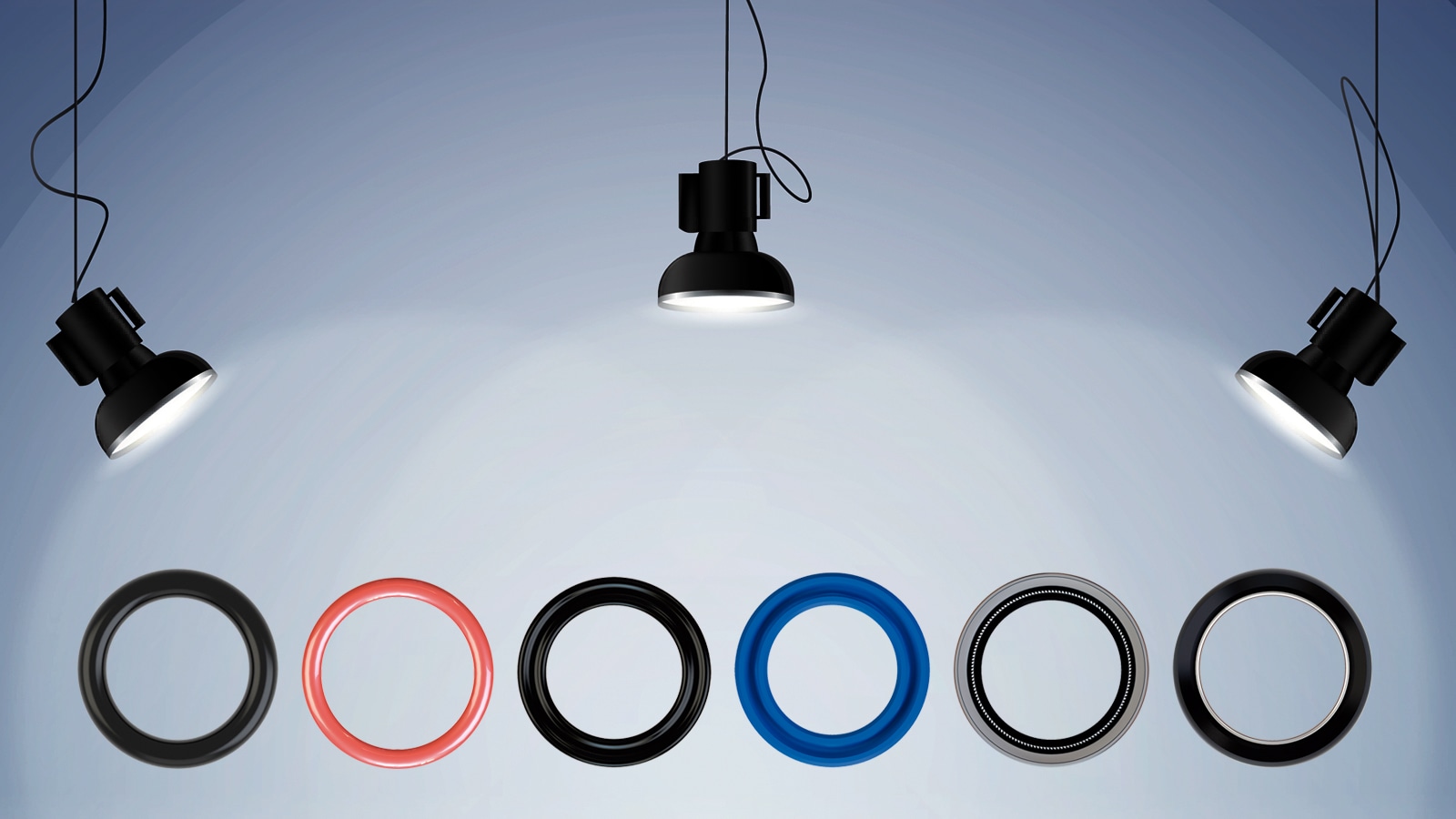

The power of images

Because a (good) image is worth more than a thousand words

The aim of all the activities we have been conducting in recent months is to enhance the image of JIOrings. We are conducting content generation activities to disclose the benefits of our seals, positioning initiatives to enable potential customers to find our seals and loyalty initiatives to ensure our customers continue to purchase from us, among others.

Our most recent contribution to the continuous improvement of JIOrings was to improve the online image conveyed by our seals. We have updated all the photos of the seals in the main range, creating 3D images of each part and of the profile of each one, as well as a video illustrating the part. In addition to improving the presentation of the product data sheet, adding relevant information such as certifications, links to the catalogue…

We are the sellers, but our customers purchase without seeing the product, paradoxes of both life and the day-to-day of all e-commerce entities. At first this may seem like a “disadvantage” when compared with traditional stores, however, we at JIOrings have been able to overcome this potential shortcoming with the new design of the seals.

We have striven for a careful and professional product image which will help us to boost our sales; an image which will provide our customers with a sense of trust and safety; an image which will clarify any technical doubts with regard to whether or not this is the right purchase, and we believe we have achieved that. What´s your opinion? Have a look at the new product data sheets:

V-Rings, versatile seals for high sealing and steadiness

V-Rings or V-Seals are one of our 5 stars products

At JIOrings, we offer a wide range of seals as one of our competitive advantages: more than 20 million parts which are different one of the other because of their shape. their material, their colour or their hardness. And If the O-Ring is the most remarkable, we also provide our clients with some other 5 stars products at the best price. In this post, it comes to V-Rings – or V-Seals – to be honoured.

The V-Ring is an elastomeric seal used for the sealing of rotary shafts without pressure. It is commonly fitted to ensure sealing against dust, mud, water, oil and other fluids. And how does it achieve that? Well, dynamic sealing results from the flexible lip to be slightly put up against a stationary counter-face, perpendicular to the shaft.

Thanks to its inherent tension, the rubber body is held in position, rotates with the shaft and enables the lip to be always in contact with the counter-face. During the V-ring rotation, the centrifugal force projects droplets or particles away from the system, thus preventing its penetration onto the surface to be protected.

All this makes the V-Ring a seal to be used in plenty of applications such as machine tools, appliances, electric motors, agricultural machines, plugs, pumps, mining machinery, cars…

Among the V-Rings range, we stock the VA model (the most used compact-designed seal on the market), the VS model (with a larger axial size, it provides a better adherence to the shaft due to its inclined shape) and also the VL one (similar to VA but with reduced sizes that make it perfect for applications with little space). We offer two standard materials: black NBR60 (IBNB01959-132001) and brown FPM60 (OZKF11163-132001). On request, we can supply VE and VAX models.

To sum up, here are below the advantages of the V-Seals:

- Low cost.

- Excellent wear characteristics and extended seal life, due to its frictional losses and heat to be kept to a minimum.

- Its use and installation are easy and quick.

- A single V-Ring can be used for various shaft diameters.

And the goods news is that all these advantages are available right now, at JIOrings. Should you require a quick quotation or to place an order with us, please log in to our e-shop. JIOrings is the fastest way to find a seal, that is the reason why we ship the same day any order placed before 1.30pm. And last but not least, we will do it through a reliable, fast and cost-effective carrier. What else can you ask for?

Axial Seals, the perfect link between speed and simplicity

RB Axial Seals, also known as Gamma Seals or Gamma Rings: use and advantages/benefits

At JIOrings, we know a lot about seals, and little by little (post after post), we have been spelling out all the relevant information on the wide range of seals and sealing products we have in our stock. For certain specific conditions of use, sealing products with a good resistance to high speed rotation are required and other types of seal no longer perform well. Sealing solutions with such specifications should be complex to manufacture and difficult to locate… However nothing could be further from the truth! It is now common knowledge that we are the quickest way to find a seal, and therefore have the seal type designed specifically for these circumstances: the RB Axial Seals or Gamma Rings.

We recommend the use of RB axial seals for applications in which avoiding water entry (or any other contaminants) is critical, such as in heavy equipments for earth moving in mining and construction work, or in marine environment. The most common use of these axial seals is for applications such as industrial gearboxes, water pump, power transmission systems, building site machinery, electric motors and rotary shafts amongst many others.

Axial seals are specifically designed to be perpendicularly fixed to the shaft at a predetermined distance from the stationary counter-face. During the rotation, the lip sticks against the counter-face under a calculated pressure that enables the perfect sealing. Furthermore, we must stress the deflector role of axial seals, taking advantage of the centrifugal force in order to improve the required sealing effect.

RB and RB9 axial seals – as well known as Gamma Rings or Gamma Seals – combine the ability of mechanical seals to work at high speed and the simplicity of oil seals.

Its shape is quite simple: a carbon-steel chromate or zinc treated metal case and a sealing lip in NBR or FKM. The metal case acts as a protector of the sealing element and is an efficient deflector as well: thus, the metal shell contributes to remove any pollution media thanks to the centrifugal force, allowing an effective drainage after immersion in liquids. Components are not bonded together as the rubber part is stretched and held in the housing thanks to its elasticity.

To summarize, we can state that the main benefits of RB axial rings (also internationally known as RB Gamma seals), are as follows:

- Ease of assembly, as their installation is very simple.

- Reduction of friction when the rotational speed increases.

- The rotary motion of gamma ring/seals, acts both as a seal and a deflector or protector, preventing any entering of external material or liquid.

- They provide a very good seal, reinforced through the action of the centrifugal force. They offer a high degree of sealing effect against contamination from grease, dirt, dust and/or water.

- Maintenance and repairs are reduced to a minimum, and when necessary their cost is low.

- They combine well with cassette seals.

- The outer ring or metal casing protects the elastomer sealing lip.

- Also bearing in mind that RB axial seals can be fitted in place of V-Ring, with the added benefit of the metal casing.

For more information on RB axial seals, please check our web page, where you can also submit a request for quotation. If you also want to place a purchase order or check availability, our user-friendly customer interface allows you 24/7 access to our online store.

U-Rings and their many uses

U-Rings or lip seals, a guaranteed range of uses

While it is a fact that O-Rings are the universal seals par excellence, used in practically all sectors of industry and other less common areas such as the jewellery sector, as we have mentioned in previous posts.

However, this does not mean these are the only seals on the market, as there is a wide variety of the same, including a type of seal which stands out from the rest: the U-Ring or lip seal.

So what makes U-Rings so special? The answer is simple: its versatility.

The perfect symmetry of the U-Ring results in a highly efficient seal and ensures excellent tightness due to the self-compression of the lips during the assembly process and the effect of opening the lips due to the pressure applied. The UN U-Ring (also known as a symmetrical or equal lip U-ring) can be assembled on both rods and pistons, and, furthermore, can be used with both single and double effect cylinders. On the other hand, D2 and D3 U-Rings can only be used on rods due to the fact the outer lip is higher than the inner lip. The PUL95 to UN and PUL93 to D2 and D3 mixes guarantee a high-performance polyurethane for all hydraulic and/or pneumatic uses.

In addition to all of the above, the product is low cost, easy to assemble and disassemble, and is highly resistant to wear and tear, so it is no surprise the U-ring is the multiuse seal par excellence. Manufactured mostly in L-93 polyurethane, a high-performance thermoplastic, U-Rings provide excellent resistance to abrasion, friction and wear, in addition to low permanent deformation.

JIOrings possesses the biggest range of UN sizes on the market, with around 1,200 standard sizes both in metric format and inches, which enables us to meet the needs of the market immediately without having to offer mechanised parts which are normally more expensive. Moreover, we market a special 4-gripper case for assembling U-Rings.

We should remind you that whenever you need to make an order for U-rings, we guarantee delivery within 24/48 hours if you are based in the Iberian Peninsula. We are the quickest way of finding a seal, and in the case of U-Rings, the range of uses is more than guaranteed.

Two compounds with our own official approval

Official approvals

JIOrings sets out to ensure the ongoing improvements of its products, the basis of our business, as well as of its services and the way the client is treated. To meet the current requirements, we have to be capable of verifying the quality and reliability of our materials, from raw materials to the final product delivered to the Client.

With this in mind, we have achieved two own official approvals for two types of silicone:

- Red FDA VMQ70 (mainly used in O-rings but also in another wide range of parts). See technical data sheet.

- Translucent FDA VMQ40 (the base of our bungs for barrels as well as other parts). See technical data sheet.

In this official approval procedure, we relied on Centro Tecnológico Riojano which, after carrying out the test in accordance with the standards in force, granted us both official approvals.

Nowadays, at JIOrings we are inn process of approval:

- OZ75201F-000017 – Black FDA FPM75 (Viton®) (extruded profiles).

- JA7206F-000017 – Red FDA VMQ70 (extruded profiles).

At present we have more than 600 compounds available, many of them officially approved by our suppliers at certified laboratories or compliant with the more common international standards. As we are unable to thoroughly detail all of these compounds, below we have set out a representative sample of the most highly rated ones.

Further information: Official approvals

Metres and metres of cord ring in different thicknesses and tolerances

Metres and metres of cord ring

When the universal joint by antonomasia (the O-ring) is not a feasible option, the cord ring may be our best alternative. In many cases in which there is a specific need for maintenance for which there is no standard O-ring, the famous “cut and paste” can get us out of tricky situations.

Here at JIOrings we have more than 50,000 metres of cord ring. It is an O-ring profile cut to the desired measurement and whose two ends stick together either by using cyanoacrylate (better known as Loctite®) which are hot vulcanised. The use of pasted O-rings is usually recommended solely for static applications; whilst vulcanised O-rings can also be assembled in dynamic applications.

From our warehouses we can supply cord ring in different standard materials and thicknesses:

- Thickness: From 1.00 to 20.00

- Tolerance (mm) NBR: ±0.20 to ±0.70

- Tolerance (mm) FPM: -0.10 / +0,30 to -0.60 / +0.80

- Tolerance (mm) EPDM: ±0.30 to ±0.90

- Tolerance (mm) VMQ: ±0.30 to ±0.90

Although on demand we can make cord ring up to 100mm thick and by tenths (e.g. 6.10mm, 6.20mm, 6.30 mm etc.) for those for which the standard does not fit them.

Furthermore, we can’t think of a better time than the month of February with its famous carnavas for presenting this item of our stock: a kit for making O-rings of any diameter, from cord ring which contains different thickness of cord, cutting blade, accessories/support and adhesive. Its use is almost exclusively industrial and is related with maintenance but there are certainly many people involved in making their home-made costume using our cord ring KIT would be just right.

Remember if you need to make an order we guarantee you’ll receive it in 24 hours if you are in the Iberian Peninsula. We are the quickest way to find a seal and if there isn’t one, the cord ring you’ll need to make it.

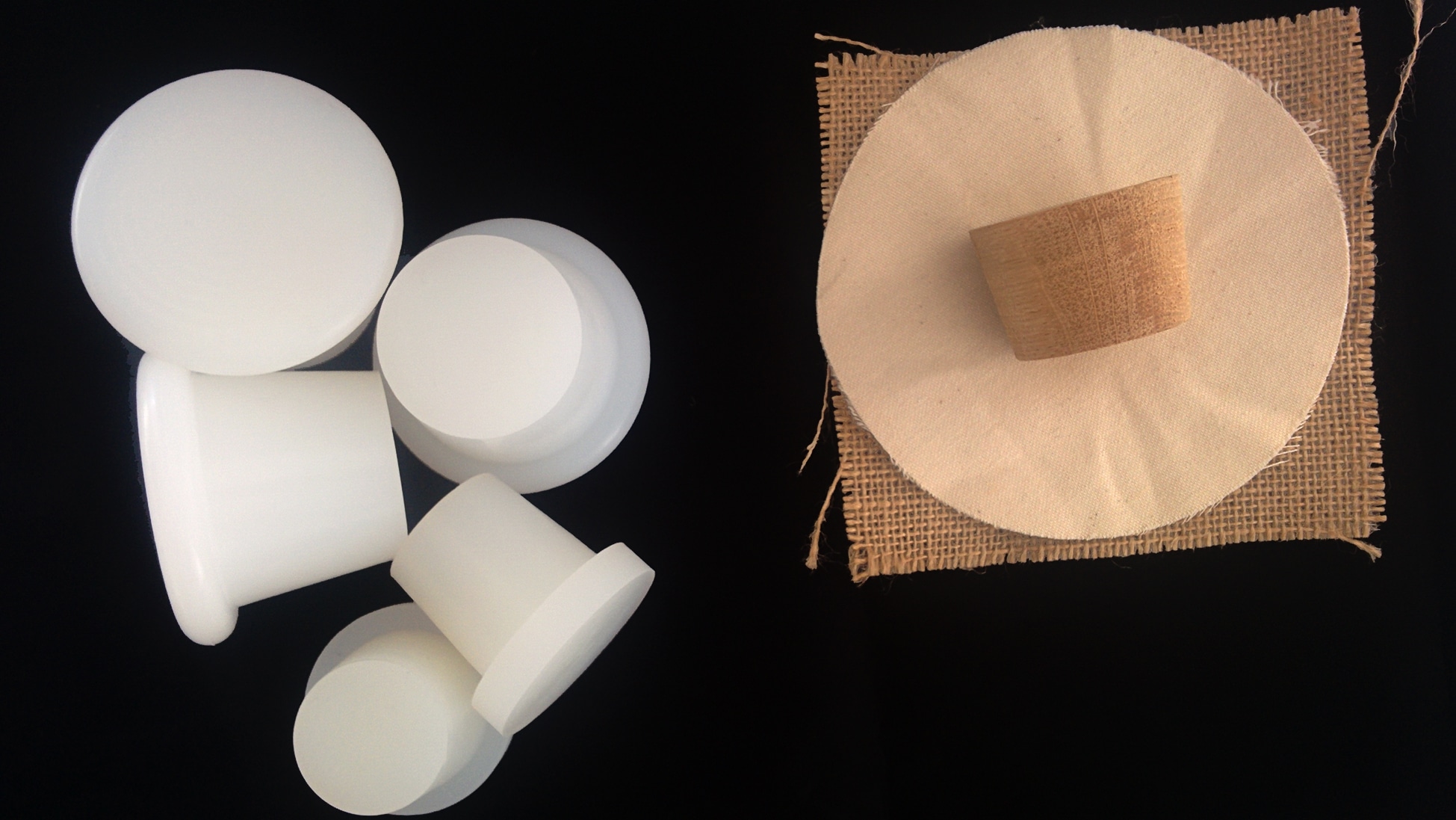

Silicon plugs for wine barrels: innovation progressing in the more traditional sectors

Nortap, silicon plugs for barrels

Our silicon plugs for barrels are made from quality materials which allow optimum wine storage in the barrel.

Tradition and modernity do not have to be antagonistic concepts. They can go hand-in-hand and result in a benefit from this alliance. This is the case of our silicon plugs for wine barrels, a sure-fire, innovative product for a sector like the winemaking one which has age-old customs.

Ten years´experience in the design and manufacture of rubber technical parts has driven us to develop this product and we are very happy with the result. Our plugs or bungs are made from high-quality materials and they adapt to the diameters of the barrel mouths used most often.

Though those best suited to bear testimony to this are our clients who include Bodegas Campo Viejo, Grupo CVNE and Rioja Alta SA. These three producers maintain and pamper the traditional wine-making methods and these age-old secrets that go to make up the essence of the broths, but, at the same time, without missing out in the advantages afforded by new technologies.

Our silicon plugs for barrels last for years by contrast to those made of wood which have to be changed every time wine racking is carried out for example. This is not necessary with JIOrings bungs which are totally hygienic and are made in line with the FDA standard (Food and Drug Administration). It is a harmless, odourless and insipid product which ensures the optimum storage of wine in the barrel.

We started marketing this product in 2015 and in 2016 we wish to consolidate, on the one hand, all the bung references we already have, with stocks which enable us to meet the demand of habitual clients and others who have begun to appear; and, on the other hand, we will gradually generate new bung references as and when demand evolves.

Basically, and as is already the case with seals and other products, here at JIOrings we also hope to become the perfect distributor of silicon plugs for wine barrels.

If we can help you with something, please feel free to get in touch.