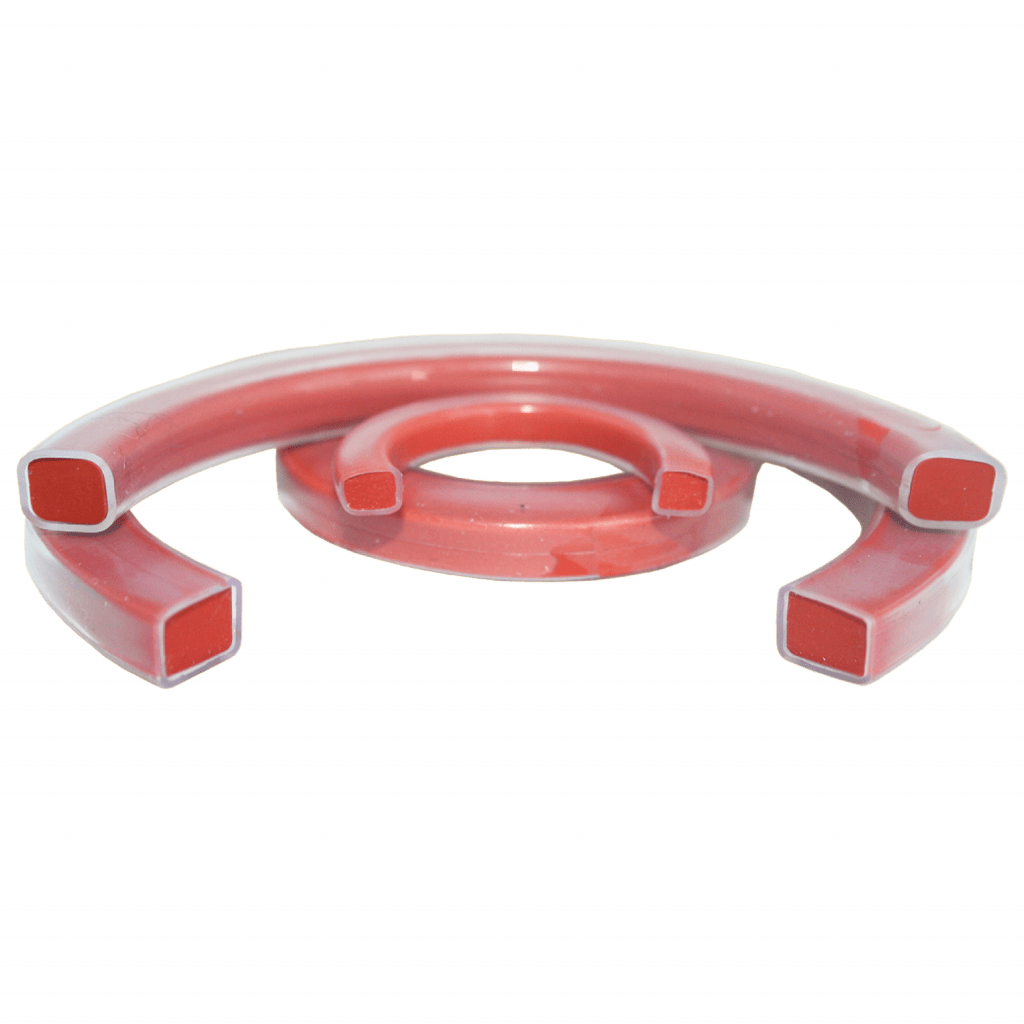

FEP Encapsulated Kamlock® Gaskets

Encapsulated Seals for Kamlock® couplings are designed as universal, non-contaminating hose coupling seals. They eliminated the need to specify different elastomers for differing applications and eliminate coupling leakage through seal gasket failure, due to chemical attack or creep of solid Teflon gasket seals. Kamlock® seals provide a superior seal for any bulk liquid transfer in manufacturing, distribution or storage.

- Inexpensive, high performance solution to many critical sealing problems.

- Combine the energizing properties of elastomers with Teflon® superior resistance to extreme temperatures and hostile chemicals.

- Are available with either Viton® or Silicone elastomer cores encapsulated with a FEP Teflon® fluoropolymer.

- Overcome the cold- ow problems associated with solid PTFE gaskets.

- Eliminate the need to specify different elastomers for differing applications.

- A superior seal for any bulk liquid transfer in manufacturing, distribution or storage.

Clear Teflon® FEP Seamless Encapsulation: Protects the elastomer core from extreme temperatures and hostile chemicals.

Viton® Core – Genuine DuPont Viton®: Viton® elastomer core energided the seal and o ers a very low compression set value.

Silicone Core: Silicone elastomer core energises the seal and performs better than Viton® at low temperatures.

Encapsulated O-rings, seals details

| O-Rings | Material | Temperature [ºC] | Check stock |

| FEP Encapsulated | Viton® Core | -20 to +205 | |

| FEP Encapsulated | Silicone Core | -60 to +200 |

Kamlock® Rectangular Seals

Encapsulated Gaskets, Kamlock® Seals, are designed as universal, non-contaminating hose coupling seals. They eliminate the need to specify different elastomers for different applications and eliminate coupling leakage through seal gasket failure, due to chemical attack or creep of solid Teflon® gasket seals. Kamlock® seals provide a superior seal for any bulk liquid transfer coupling in manufacturing, distribution or storage.

- Universal gasket with extreme chemical resistance and wide temperature range.

- Leak free performance – low compression set and elastomer core energizer avoids cold ow leakage commonly found in solid PTFE.

- Non-stick surface with low co-efficient of friction (0.1 to 0.2) allows easy installation and removal.

- Sanitary, sterilisable and FDA compliant encapsulation eliminates contamination.

Rectangular FEP Gasket For Kamlock® Couplings

| Coupling Nominal Size | Dimensions | ||||||

|---|---|---|---|---|---|---|---|

| INCHES | MM | ||||||

| INCHES | MM | A | B | C | A | B | C |

| 0.500” | 12.70 | 1.024” | 0.669” | 0.157” | 26.0 | 17.0 | 4.0 |

| 0.750” | 19.00 | 1.375” | 0.875” | 0.218” | 35.0 | 22.2 | 5.54 |

| 1.000” | 25.40 | 1.563” | 1.063” | 0.250” | 39.7 | 27.0 | 6.35 |

| 1.250” | 31.70 | 1.938” | 1.359” | 0.250” | 49.2 | 34.5 | 6.35 |

| 1.500” | 38.00 | 2.188” | 1.625” | 0.250” | 55.6 | 41.3 | 6.35 |

| 2.000” | 50.80 | 2.625” | 2.000” | 0.250” | 66.7 | 50.8 | 6.35 |

| 2.500” | 63.50 | 3.125” | 2.375” | 0.250” | 79.4 | 60.3 | 6.35 |

| 3.000” | 76.20 | 3.719” | 3.000” | 0.250” | 94.5 | 76.2 | 6.35 |

| 4.000” | 101.60 | 4.875” | 4.000” | 0.250” | 123.6 | 101.6 | 6.35 |

| 6.000” | 152.40 | 7.063” | 6.000” | 0.250” | 179.4 | 179.4 | 6.35 |