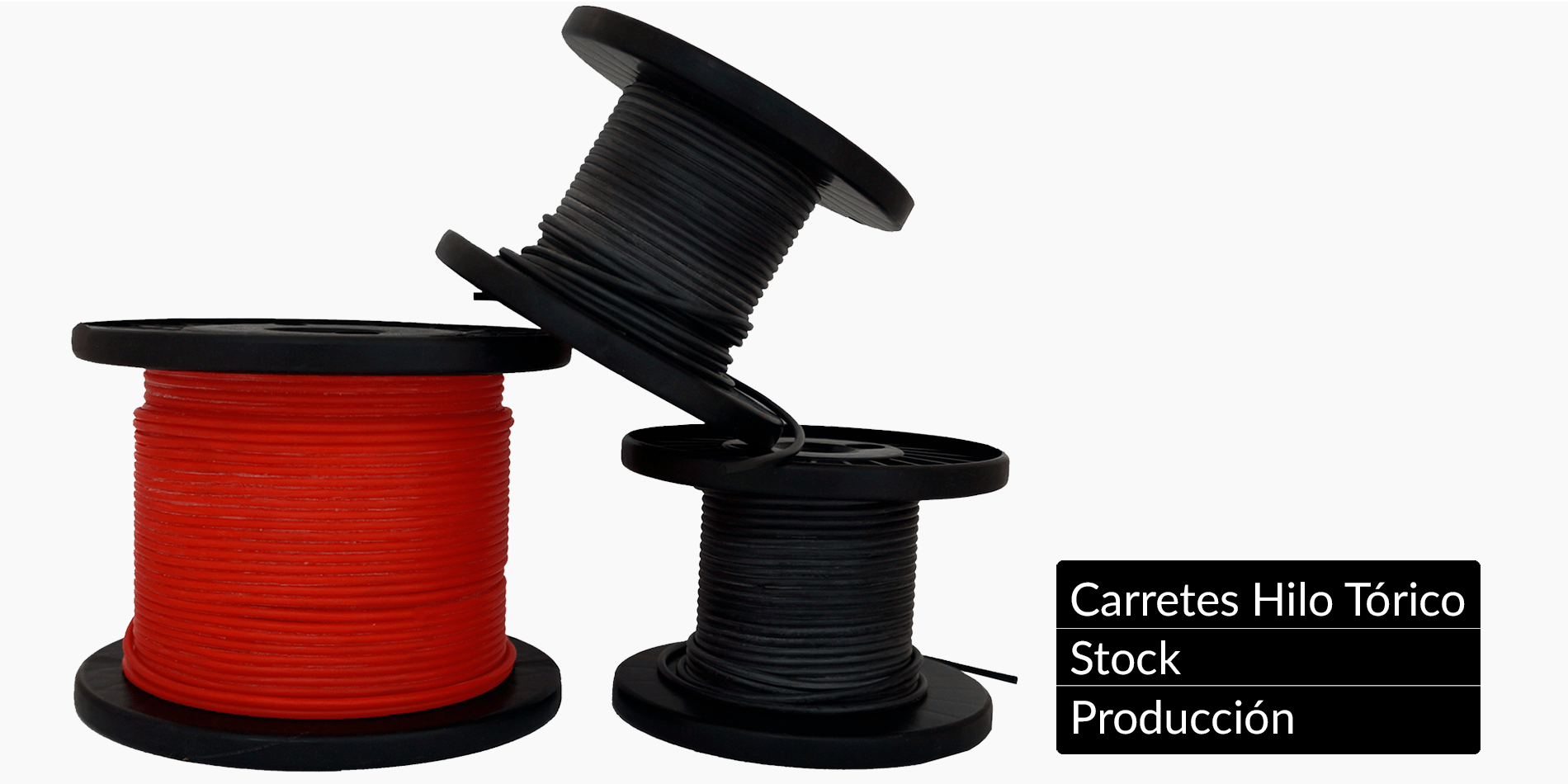

Cord-ring spools, versatility and quality assured

Cord-ring spools, the best choice

What is a cord-ring?

Cord-ring is an extruded profile of calibrated circular section that is manufactured in the most common O-ring thicknesses. At JIOrings, we have cord-ring spools in stock ranging from 1 mm to 30 mm in bull rope diameter, in different lengths (spools of 5, 10, 25, 50, 100 and 200 metres). As if that were not enough, we also have the possibility of supplying spools with other technical characteristics upon request.

What is the cord-ring used for?

The cord-ring is an excellent solution for the static sealing of lids as it allows to build by seating the O-ring to the exact measurement required for each occasion.

Furthermore, O-rings can also be manufactured by hot vulcanization from the cord-ring. This makes it possible to manufacture virtually any O-ring dimension without the need to invest in an expensive mould for its manufacture. The O-ring made from a cord-ring represents a world of solutions with practically no restrictions. The cord-ring allows for from only one unit (in a multitude of materials, thicknesses and colours) the manufacture of the desired O-ring.

Cord-ring stock

We have a wide range of cord-ring spools. Only in stock, we have more than 1,650 spools:

• Black NBR70 (Perbunan® Arlanxeo)

• Green FPM70 (Viton® Chemours)

• Black FPM75 FDA-approved (Viton® Chemours)

• Translucent VMQ 60 FDA-approved (Xiametre® Dow Corning)

• Red VMQ 70 FDA-approved (Xiametre® Dow Corning)

• Black EPDM70 FDA-approved (Keltan® Arlanxeo) for drinking water

• Black EPDM70 (Keltan® Arlanxeo)

• White EPDM70 FDA-approved (Keltan® Arlanxeo)

• Black CR70 (Neoprene® Dupont)

Approvals of our spool ranges

Some of these spools have the certifications required by the food, beverage and pharmaceutical industries, among others, such as the FDA approval or their use for drinking water.

Advantages of buying at JIOrings

We have one of the widest ranges of cord-spools in stock in the peninsula but we can also manufacture intermediate measures in short or medium series with a short delivery time, in different materials derived from rubber, with high quality standards and that meet with the technical requirements that each customer demands.

We are experts in sealing, we have more than 32 million sealing gaskets: 30 million O-rings (standard, encapsulated, custom-made…), 1 million quad-rings, 225,000 back-up rings (BUR), 200,000 v-rings, 70,000 bonded seals, 40,000 rotary shaft seals, 40,000 hydraulic seals, 25,000 wiper seals, 6,000 axial seals…

We supply all our seals with the highest level of quality, with an unbeatable customer service and fast and efficient delivery.

2017 Annual summary

2017: giving the best of ourselves

F I G U R E S

It has been a good year and we have now had several such in a row. Each year, the objectives set company-wide by the Management team are more ambitious and it is, therefore, doubly satisfying when they are achieved. We have done this once again in 2017. This year we have grown, both in terms of stock and staff. We have broken the barrier of 30 million seals in the warehouse:

• 30,000,000 O-Rings • 1,000,000 X-Rings • 225,000 Back-Up Rings (BUR) • 200,000 V-Rings • 70,000 Bonded Seals • 40,000 Rotary Shaft Seals • 40,000 U-Rings • 25,000 Wiper Seals • 6,000 Axial Seals or Gamma seals • 1,650 Spools of Cord-RingWe have also broken the 12-employee barrier. First, with the hiring of Iñaki Bilbao in January in the Export Department and then Unai Pereda in September in the warehouse. Both have adapted very well both to the intense work rate and to the environment.

In September, we broke records left, right and centre in terms of order backlog, which we broke once again last November (with sales totalling €220,000). This year, each quarter has been the best in JIOrings‘ history, indicating that we have maintained a very high work rate among all departments throughout the course of the year.

A major investment was made to improve shared facilities at JIOrings this year. We now have a new meeting room, where we can welcome our clients in a comfortable and convenient manner; a kitchen for everyday use by the employees and for our regular coffee and potato omelette event on Fridays; as well as a multi-purpose leisure room, which will soon host the first edition of our ping pong tournament. The new JIOrings offices are designed to be open and comfortable spaces in which to carry out all the day-to-day commercial and administrative work and to receive clients and suppliers.

Q U A L I T Y

At the beginning of the year, we obtained ISO 9001:2015, issued specifically on the 21st of February, following the successful conclusion of audits by BUREAU VERITAS, which certified that our Quality Management System had been appropriately implemented in accordance with the latest version of UNE-EN ISO 9001:2015. This is another step that has allowed us to adjust workflows, redefine strategic objectives and see that we are well on our way to excellence.

At JIOrings, we work to ensure that our seals meet quality, health, safety, environmental and social responsibility standards in virtually any market. For this reason, in addition to complying with REACH and RoHS standards, we hold major official approvals from our suppliers and we are making an extra effort to obtain in-house approvals for some of the most successful mixtures.

In this respect, we have taken a significant step forward with the certification of JIOrings Nortap® silicone plugs, which, in addition to being FDA compliant, comply with the requirements established by the BfR, Bundesinstitut für Risikobewertung (Federal Institute for Risk Assessment).

C O M M I T M E N T

It is a word that defines us. With each new client we try to reach the degree of commitment necessary to satisfy their expectations. For us, making sale means convincing them that we are the best option (the quickest way to find a seal) and for that, we must earn the trust of each one of our clients each and every day. To offer a quality product with excellent service. With more than 1,500 customers (of which 169 are clients gained this year), we sell to more than 30,000,000 seals to 35 different countries, this year we have included expanding our sales to countries such as South Korea, Hungary and Estonia. All this without neglecting the national market, which accounts for 80% of our total client portfolio.

For us, the commitment is reflected in the quality of the product, in the sales processes and in the marketing of each and every one of our seals.

This year, in addition to all the loyalty activities we have been carrying out, we have placed special emphasis on the scheduling of orders. This is because it is the way in which we can improve prices, guarantee stock, avoid unforeseen events and meet all delivery dates agreed with each customer.

S P E C I A L D A Y S

We sincerely believe that the company influences and is influenced by its environment. Hence, a great deal of our efforts is focussed on achieving the most positive working environment possible, where each and every person feels part of the company and, in addition actively partners in local projects of various kinds.

To achieve the first objective, we carry out specific activities to promote teamwork and unity among employees with the aim of improving coordination between everyone and the relationship with the company: meals outside the working environment, celebration of birthdays, an annual ping pong championship, participation in popular races etc., and an annual activity, which this year saw us sampling wines in La Rioja.

As for the second area, it should be noted that during 2017 we continued to support sports via the JIOrings Cycling Team and the JIOrings Running Team, as well as via sponsorship of several sports teams (Club de Ajedrez Conteneo Bilbao Haitzak [Chess], Galdakao Boleibol Taldea [Volleyball] and Jon García Tagle’s participation in the 2017 Kneeboard World Championship, among others.). Apart from all these not-for-profit link-ups, throughout the year we have carried out a range of activities to raise awareness of Tourette Syndrome. By means of “Un paso más por el síndrome de Tourette” (Amaya Álvarez) and “Pedaladas por el Tourette” (Ángela Domínguez ), we want to do our bit in terms of raising awareness of and normalising this disorder.

F U T U R E

As every year, we will work hard to expand the stock of the seals most in demand by our customers: seals made from blends with in-house approvals, different sizes of plugs for export to the French, Portuguese and Latin markets, cord-ring in various materials….

In addition, in 2018 we want to redouble our efforts to shorten manufacturing lead times and improve agreements with our logistics suppliers, always with the aim of remaining the quickest way to find a seal. In addition, by 2018 we have challenged ourselves to improve the website experience and boost online shopping, a way to save both time and money. In January, we expect to conclude this first phase of improvement in our facilities. We do all of this without losing our focus as a young and dynamic company and one that meets the needs of our clients.

JIOrings, a real asset

The importance of approvals

Day after day the O-rings have to meet more and more requirements in matters of environment and security. By the same token, public organizations impose more and more rigorous and restrictive requirements on materials or compounds that form the seals which are aimed to get in contact with water, gas, food products, chemistry products…

In JIOrings we are really committed to preserve the quality and security of the compounds that form our seals. In order to increase the value of our products, gain competitive advantage and develop a reliable brand, we are immersed in a continuous certification process that comprises the following points:

· Our own approvals: In this case we have different compounds with our own homologation as well as some others which are undergoing the process to be homologized.

· Our main suppliers’ approvals: As distributors we require of our suppliers all the certifications our clients need.

· In addition, in JIOrings, being distributors, we meet the standards of REACH regulation as well as the standards of RoHS directive.

Our own approvals

In some cases, when some compounds have been really successful (for instance, those compounds in stock offered in different measures or compounds which have been highly demanded by our clients), we decided to take a step forward and homologate the mixture (such as the food-grade silicone JA7006F-134662) on our own. That way we can provide our clients with a verified and warranted quality level according to the results obtained in the testing carried out by an independent laboratory. In these cases, the achievement of the homologation, as stated by the standards of the American agency FDA (Foods and Drugs Administration), implies that the technical file should have the original certification of the homologation.

In some other cases, we feel indebted to homologate a specific mixture due to the market’s demands. When we started the new stage of internationalization for our silicone plugs for wine barrels we soon realized that, beyond the quality of the pieces, we also had to pay attention to all the documentation related to the quality of the mixture we were about to provide to our buyers. In the first stage, we managed to get the FDA homologation, but as in some cases it turned out not to be enough, we got on to work. Thanks to the inestimable collaboration of Intertek, we achieved the BfR (Bundesinstitut für Risikobewertung – The German Federal Institute for Risk Assessment) certification, which meets the requirements of the European Union’s 1935/2004 regulation and it allows us to export our plugs all around the world, and with all the guarantees.

Homologation process

In general, laboratories require rubber samples that are called slabs. They are semi-finished pieces, in a standardized size that allow carry out some tests which are defined by the most common international regulations (ASTM, DIN, ISO, etc…). The aforementioned tests are executed under really strict conditions and they will be only homologated in case the results are within the established limits.

So far we have certified all the approvals on our own with the help of two close companies: the Technological Centre of La Rioja and the Intertek’s branch in Bilbao. However, we would not discard, in case it would be necessary, the help of a foreign laboratory for specific approvals, such as that of the drinking water.

And now, what?

We firmly believe that quality is an added value that JIOrings offer in each sale. We constantly work to ensure that our seals meet all quality, health, security, environment and social responsibility standards in nearly all markets. In addition, we are aware our clients appreciate the efforts we are making in the last years.

We inform you we have already updated the “Official Approvals” section in our web. You could find there a table where we indicate all the approvals by compounds. In case it is a specific mixture we homologated, you can download it automatically. In the other cases, however, we indicate the adequacy of the approvals for each mixture. This table contains information that we will be updating just as we get more approvals, be our own approvals, be approvals certified by our suppliers.

The back-up rings (BUR) and the O-Rings, the perfect tandem

Back-up rings + O-Rings = 100% compatible

Some time ago we spoke about the O-Rings and how good they were when a risk of extrusion from the housing could exist. The O-Rings create the seal effect pressing against the housing parts that hold it, but the capacity of the ensemble depends basically on these three factors: (1) the correct choice of the O-ring, (2) the surface finishing of the housing and (3) the play between the elements.

When the O-Rings are called to exercise the seal in circuits in which the pressure reaches high levels, one of the risks to be considered is that of the ring extrusion from the housing. Such a risk is increased when the O-Ring compound is soft.

In order to avoid this risk we may rely on back-up rings (BUR), also known as anti-extrusion rings. The back-up rings are designed to guarantee a high level of seal performance in contact with the O-Ring. Otherwise said, they aim to protect the O-ring so that it may develop its task.

The choice of the right back-up ring lies in the following points which should be born in mind:

• The compounds chosen for the back-up rings must meet all of the compatibility requests of the fluids requested of the O-Rings.

• The hardness to support the other pressure loads must be suitable.

• The resistance to the usage and ageing must be high, to guarantee good performance for the entire life of the O-ring to which they are required to protect.

• The measure of the back-up ring, of course, must go with the O-ring that protects.

If the choice is the correct one the back-up ring will provide an excellent performance, as a back-up element for the piston and shank seals that may be generally found in hydraulic static circuits and hydraulic dynamic circuits. The back-up ring could be located in the rear or under the pressure of the sealing element which is holding, although there could also be different housings that hold two back-up rings, each from a different side of the O-ring.

At JIOrings we have NBR90 back-up rings according to the Parker® Standard:

From: -006 to -460 (ø3,56mm to 394,31mm).

Thickness: 1,14/1,24 1,14/1,35 1,02/1,27 1,52/1,93 2,44/2,97.

* Under request, we may provide different measures and other materials.

If you want to purchase them in our online store you can find them by product (BUR or Back-Up Ring) and size. You can also take the British Standard number that the O-ring has as a reference (for example, BS211) to search in the “Description”.

| Type | Profile | Material | Pressure [Bars] |

Temperature [ºC] |

Check stock in real time |

| Back-up rings |  |

NBR | ≤400 | -20º to +100º |

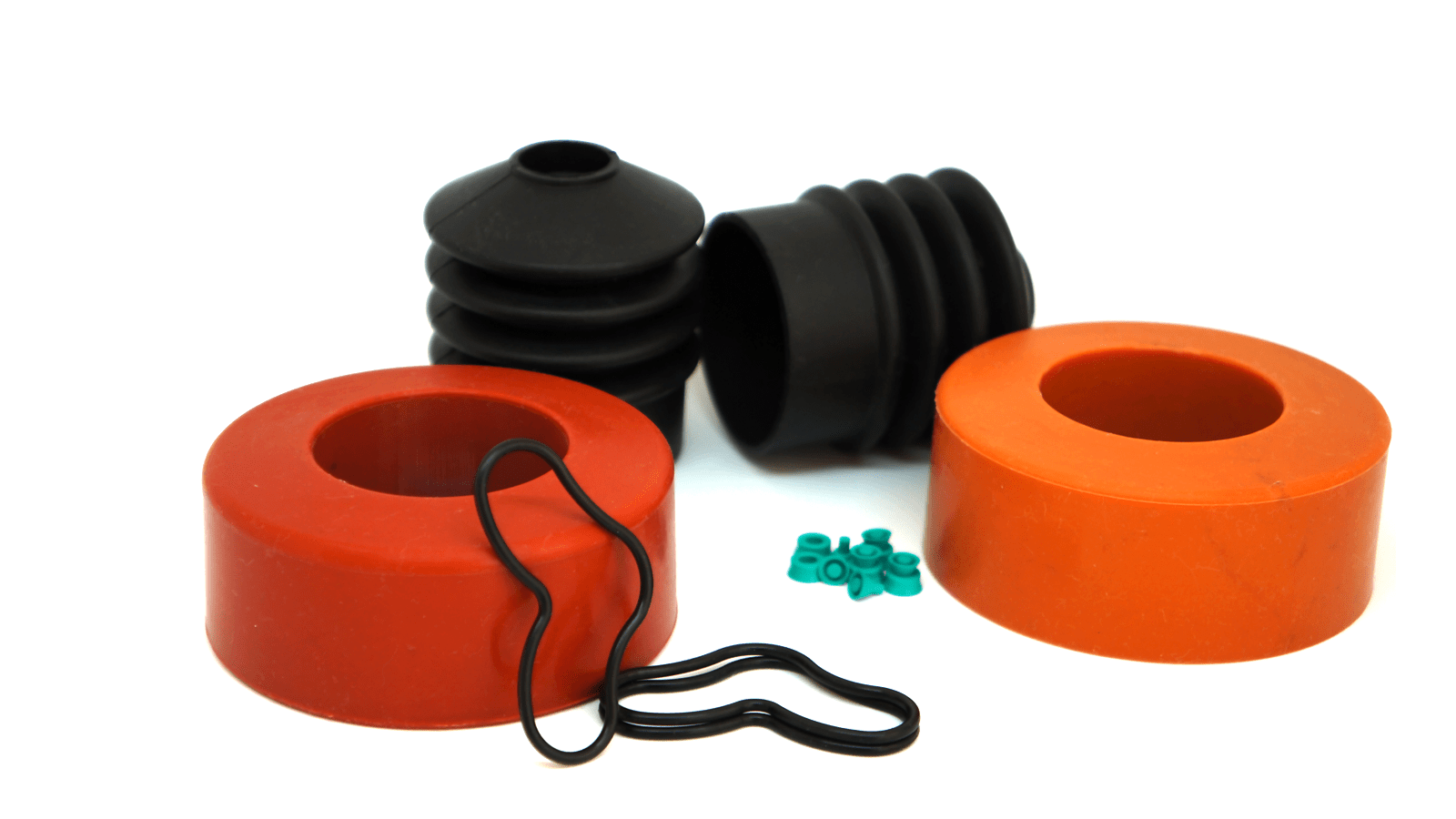

At JIOrings we also manufacture special pieces to measure

When special manufacturing turns out to be the solution

At JIOrings, as in life, standard stuff is sometimes no longer worth it. When it happens that we cannot fulfill our client’s needs with any of our pieces from our large stock, it is necessary to create a special piece.

This kind of piece based on a drawing or sample is manufactured for a specific client and must meet some specific requirements. We design and develop pieces of specific manufacturing according to our client’s needs. Thanks to our experience and our partners (recognized laboratories and national and international factories) we can successfully tackle with great challenges.

The manufacturing process of special pieces at JIOrings aims to achieve our clients’ satisfaction. In the first phase, we examine each client’s needs: how the pieces will be like (hardness, compression set, elasticity, resistance), which applications will they have… We design a mold based on a drawing or sample provided by the client and we take into account the specifications of each piece. Once the mold has been made, we manufacture a pre-series which is sent to the client so that they might check it and make all the necessary proofs. In other words, we properly homologate the sample. Once the piece has been approved, we put all hands on deck and we start producing the special pieces that have been asked, without forgetting the deadlines and quantities.

There are many advantages for making special pieces at JIOrings:

- We examine each client’s needs and we offer a measured solution.

- We have more than 14 years experience in the sector.

- We manufacture molds or equipment at very low cost.

- We can produce special pieces in short edition.

- We manufacture pieces that meet required international norms (food, drinking water…).

These are some of the lately produced pieces that we have manufactured:

| Part | Material | Features | Description | |

|

Collar | FPM 70 SH A Green |

|

Pumping equipment. |

|

Fuse holder attachment | VMQ 35 SH A Dielectric Red RAL-2001 |

|

A special mixture developed for fuse holders with special insulating features, low residual deflection, and with personalised hardness and colour. |

|

Quad-Ring | EPDM 80 SH A Peroxide Black (4442-N69) for potable water |

|

Included in assembly of pressurised tanks for the treatment of potable water. |

|

Cap | Neopreno 50 SH A Black |

|

Dust caps for compact gas cells. |

|

O-Ring | EPDM 65 SH A |

|

O-ring with a rectangular perimeter for pressure relief in gas cells. |

|

Shaped seal | NBR 70 SH A Black |

|

Sealing parts with a toroid cross-section for fluid control units which measure the oil that is being dispensed at each service point in an automobile repair shop. |

Aseptic seals and their high hygienic and asepsis level

Aseptic seals are mainly used in chemical, pharmaceutical and food industries

Without any doubt, the main seal is the O-ring, the most known, worldwide used and, many other times, the seal JIOrings identifies itself with. Nevertheless, when it comes to chemical or pharmaceutical applications, aseptic seals provide tightness to the flange and the tube fitting as well as the necessary hygiene.

At JIOrings we offer a wide range of seals and each one is ready to use under any circumstance. Actually, seals may be extremely important in certain situations as the materials they have been manufactured with must be the appropriate ones for being used in biotechnological and pharmaceutical processes that required a high level of hygiene and asepsis. And there is exactly where our seals come into play.

Aseptic seals or Hygienic Seals are mainly used in chemical, pharmaceutical and food industries. These fields are normally highlighted because they manufacture and commercialize products in large scale, and if any were about to be modified, the product would turn out to be defective and almost useless.

For that reason, it is of paramount importance to use the best aseptic seal so that everything remains correct and precise in these industries. At JIOrings we offer the best aseptic seals: we make them in different materials, compositions and colors. All of them are homologized by the FDA norm and have the UPS Class VI certification; besides, there are many other homologations from important national and international suppliers.

On the one hand, we offer winged clamp seals (its wing prevent the seal from falling off when it is opened) and, on the other hand, we have D-Rings, available in different materials, such as EPDM, NBR, VMQ, FPM, CR, EPDM peroxide and PTEE.

If necessary, you can always get more information in order to get to know deeper our asepsis seals. However, if you want to require a quotation or shop directly you are in the best place.

The wrong election of a seal could have terrible consequences

If there is any gas, choose RGD, ED Resistant or AED seals

The O-ring, the most universal seal, is the most used seal in fluid-tights because of its excellent effectiveness-cost relationship. Simple as it may be, it can also be manufactured in many different materials and it has a wide range of uses. When it comes to choose the most suitable material, the fluid to be tightened and the temperature are elements of paramount importance to make the good choice. By the same taken, History has shown us that no failure must be allowed.

NASA’s Challenger Space Shuttle could be one of the most well-known and tragic cases, when it broke apart 73 seconds into its flight due to the wrong choice of an O-ring. The seals used in the shuttle were FKM seals, and they were not designed to fly under unusually cold conditions as in this launch, so the seals lost their elasticity. As a result, seals lost their capacity to return to their original shape after the foreseen movement and this led to the disaster.

Nowadays, more and more clients ask us for O-rings for different fields (such as pharmaceutical, aeronautic, chemist, biomedicine, drinking water, food, gas industry…) and applications with high standards. Indeed, we just want to highlight in this post the consequences of the gas that may result in because of a wrong choice, as high pressure applications need the right seal for being efficient.

The term RDG (Rapid Gas Decompression), also known as ED (Explosive Decompression), is one of the main causes for tight failures when using seals, especially in many high pressure processes. It is a phenomenon that occurs when a pressurized gas reaches the outside very quickly and makes rubber seals from the equipment fail.

To avoid this risk, at JIOrings we offer RGD, ED Resistant or AED (Anti-Explosive Decompression) O-rings which are specifically manufactured to prevent this failure from happening and endure the quick gas decompression. The most commonly used material for RGD certified O-rings is Viton® or FFKM®, but they can also be manufactured with different materials, such as HNBR, Aflas® or FFKM.

Wipers, seals preventing the entry of dirt

Metal-cased wipers, worldwide known as "wiper seals"

Wiper seals maintain sealing contact to the piston rod when the equipment is stationary (static, no reciprocating motion of rod) and in use (dynamic, reciprocating rod). Without a wiper seal, the retracting piston rod could transport contaminants into the cylinder, and that would be disastrous. If outsider contaminants enter the hydraulic system, the contaminated hydraulic fluid can rapidly wear away axels, block filters and damage mechanized surfaces.

Wipers or wiper seals are hydraulic seals. Hundreds of wipers can be found in the market, but we could make a clear division between flexible wipers and rigid wipers (also known as metal-cased wipers). The main difference between them is that flexible wipers (made of polyurethane or rubber) are assembled in closed cartridges whereas rigid wipers (made of polyurethane o rubber with an external metal reinforcement) are used in opened or semi-opened housings.

As the name clearly states, wipers are commonly used to wipe or scrape away dirt from axels or shaft as well as prevent external particles, shavings or humidity from entering the hydraulic cylinders. Indeed, wipers operate with a wide range of applications and environmental conditions, such as dust, countless residues and surrounding environment conditions.

Polyurethane wipers (with single lip static water-tightness) are used to prevent water or dirtiness from entering the housings. These hydraulic seals are most importantly used in mobile hydraulics or agricultural equipment. However, they can also be assembled in many other applications.

Even if wipers don’t function with pressure, they may be subjected to strong charges. Generally, metal-cased wipers tend to be more resistant than flexible wipers and they are normally assembled in opened or semi-opened housings. Once functioning, metal-cased wipers remain in the housing as its outside metal part, when contacting with the metal of the system, guarantee the perfect attachment.

At JIOrings, the quickest way to find a seal, we mainly distribute MW (NBR + steel) compositions for rigid wipers, ME1 (polyurethane + steel), ME2 (polyurethane + steel) and DH04 (polyurethane) for flexible wipers. In any case, in the standard stock section, you can view the wipers we generally have in stock in the warehouse. If you can’t find it, contact us without any doubt.

Now more and better cord-ring

Throughout the year, more and more customers have been requesting spools of silicone cord-ring and as at JIOrings we love to satisfy your desires, we have decided to take the plunge… and in a big way!

Not only do we now have a large stock of spools manufactured in Xiametre® of the prestigious Dow Corning brand, but we also have spools available in Viton® original, of another presigious brand, Chemours. And because we never leave things half-done, we have applied to the CTR for the approval of both materials for use with food.

Quality, price and availability! Once again, we are indisputably the fastest way to find a seal.

FDA VMQ70

Trade name: Xiametre® (Dow Corning)

Colour: Red

Hardness: 70 SH A

Temperature range: -55 to +200 °C

FDA FPM75

Trade name: Viton® (Chemours)

Colour: Black

Hardness: 75 SH A

Temperature range: -18 to +220 °C

How to use cord-ring

By joining the ends of the extruded cord-ring, you obtain O-rings with different measurements from the standard sizes. The process is simple, you just have to cut the length of the desired circumference and glue the ends together, previously overlapped at 45º. The cord-ring is usually used in cases of static sealing, large flanges or container lids, among other applications.

The cord-ring can be glued cold or warm-vulcanized. O-rings glued cold must respect the thermal and chemical limits of the glue and the characteristics of the elastomer and are used exclusively in static applications. In contrast, vulcanized O-rings can be used in dynamic applications.

The advantages

The advantages of cord-ring make it a highly versatile option:

- Cost savings, because there is no need to manufacture moulds to obtain the desired O-ring from the the cord.

- There are no size limits for large diameters.

- Tolerances can be more accurate than in moulded rings.

- The rings obtained from the cord have no burrs.

- Faster manufacturing.

- Suitable for use with food, pharmaceutical and potable water.

The stock

Availability of Xiametre® Cord-Ring Spools

| Spool (m) | Thickness (mm) | Material | Hardness SH A | Color | Approvals |

| 50 | 1,78 | VMQ | 70 | Red (Xiametre®) | FDA |

| 50 | 2,50 | VMQ | 70 | Red (Xiametre®) | FDA |

| 50 | 2,62 | VMQ | 70 | Red (Xiametre®) | FDA |

| 50 | 3,00 | VMQ | 70 | Red (Xiametre®) | FDA |

| 50 | 3,53 | VMQ | 70 | Red (Xiametre®) | FDA |

| 50 | 4,00 | VMQ | 70 | Red (Xiametre®) | FDA |

| 50 | 4,50 | VMQ | 70 | Red (Xiametre®) | FDA |

| 25 | 5,00 | VMQ | 70 | Red (Xiametre®) | FDA |

| 25 | 5,33 | VMQ | 70 | Red (Xiametre®) | FDA |

| 25 | 6,00 | VMQ | 70 | Red (Xiametre®) | FDA |

| 25 | 7,00 | VMQ | 70 | Red (Xiametre®) | FDA |

| 25 | 8,00 | VMQ | 70 | Red (Xiametre®) | FDA |

| 25 | 9,00 | VMQ | 70 | Red (Xiametre®) | FDA |

| 25 | 10,00 | VMQ | 70 | Red (Xiametre®) | FDA |

| 25 | 12,00 | VMQ | 70 | Red (Xiametre®) | FDA |

| 25 | 15,00 | VMQ | 70 | Red (Xiametre®) | FDA |

Availability of Viton® Cord-Ring Spools

| Spool (m) | Thickness (mm) | Material | Hardness SH A | Color | Approvals |

| 25 | 2,00 | FPM | 75 | Black (Viton®) | FDA |

| 25 | 2,50 | FPM | 75 | Black (Viton®) | FDA |

| 25 | 2,62 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 3,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 4,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 4,50 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 5,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 5,33 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 6,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 7,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 8,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 9,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 10,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 11,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 12,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 13,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 14,00 | FPM | 75 | Black (Viton®) | FDA |

| 10 | 15,00 | FPM | 75 | Black (Viton®) | FDA |

Happy new year on behalf of everyone at JIOrings

Another year with a pleasant aftertaste

We bid farewell to 2016 satisfied with the job we have done and with the rewards earned and (how could we not) thanking all of our clients and suppliers for continuing to rely on JIOrings.

2016 comes to an end and, once again, it is time to briefly summarise to help us analyse the steps we took (both for better and for worse) during the last twelve months, to reflect on our annual objectives and establish new challenges for the upcoming year.

And if we look back over it, we can see that 2016 was another excellent year for us. The reward for our daily commitment and teamwork is the reaching of some of our important milestones that we would like to share with you in this post.

Sales record and market expansion

We have done it again. This year we have succeeded in surpassing several of our historical turnover records and key achievements for the future of the company. Over our twelve years of existence, we have handled more than 4,700 clients, sold more than 200 million seals, and sent more than 75,000 packages by land, sea, and sky to 20 different countries.

Over the course of 2016, we have managed to add more than 100 new clients to our portfolio, thanks to the work of our salesmen (Óscar, Cesar, and Arkaitz) and of all the marketing and communications work carried out (Silbia). Furthermore, in November, we beat the record for monthly orders, with it having the largest orderbook and turnover in the entire history of JIOrings. The warehouse workers (Fernando, JuanRa, Gonzalo, and Laura) have not stopped preparing packages. Thanks to the brisk pace throughout the year and, above all, to the results from the previous month, this year we are going to top the annual turnover record, 1.5 million more than last year. The Accounting Department, headed by Maite, is still celebrating ;D

We hope to continue growing in 2017, and quickly, around 10% according to our Executive Director (Iñigo).

Immersed in the certification of our quality system

We find ourselves in the middle of the quality certification process according to standard ISO 9001-2015. Our objective is to achieve this by January 2017 and, thus, to be able to address new needs that we recognised among our clients. What better way to start the year?

The process of obtaining the ISO standard has made us perform a comprehensive improvement of our quality management system in order to make it comply with the international standard. We always have an eye out for ways to improve our products and services in order to be able to offer you the best product with the best service.

Stock expansion

In order to be the quickest way to find a seal, we must be able to meet the majority of our wide range of clients’ needs. As a result, over the last twelve months we have focused on increasing our stock of O-ring seals made from Viton®, in the French R range in VMQ70 FDA red, NBR90, and NBR50. Similarly, we have also expanded our stock of spools of cord stock made from Xiametre® and Viton® original, both materials certified for food use by the CTR laboratory.

However, we have not focused on expanding stock of just these two products, but rather also in supplying our warehouses with the main ranges of all of our major products: X-rings, U-rings, V-rings, RB gamma seals, rotary shaft seals, etc. Our Purchasing department (headed by Jean-Albert) did not have time to get bored this year.

We keep collecting certifications

One of JIOrings’ competitive advantages is its rapidity, but another is that we also offer the best products. To do this, we always show the various certifications that verify that our products are of the highest quality. And in 2016 in this respect, we have certified our own new mixtures for moulded silicone seals (VMQ70 FDA red, VMQ40 FDA translucent, VMQ40 FDA brown…), among others, as well as for extruded profiles, such as Viton® (FPM75 FDA black, silicone VMQ70 FDA red…).

As this is a process that never finishes, we have created a new section on our website where we display all the official approvals that we have obtained.

Because we know that trust is foundational to our relationship, throughout 2016, we wanted to share some moments of our working and social life with you. That is why we recorded our corporate video about how we work at JIOrings, we publish photos of our annual outing to foster inter-personal relationships and a positive atmosphere, we share photos from several Fridays where we have celebrated one of our staff’s birthday… And created a lot of content on our social networks so that you can get to know us better.