Are you familiar with the special types of treatment applicable to O-rings?

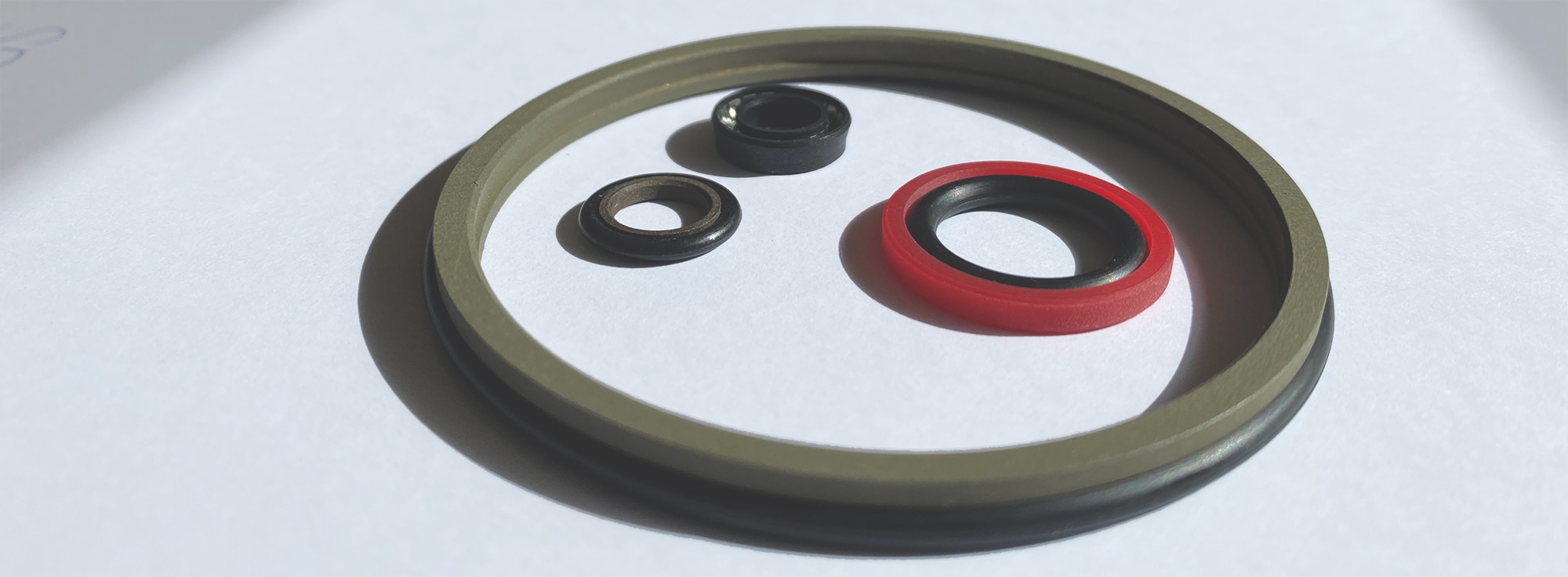

Treatment designed to improve the performance of O-rings

Standard elastomer O-rings sometimes need to undergo special surface treatment. This will enhance the performance of the equipment and levels of productivity in the assembly and mounting processes in which these seals are used.

We at JIOrings treat the surface of O-rings using special cleaning, immersion or coating processes, with the aim of reducing friction and adhesion in order to achieve a permanent lubricating effect and to facilitate the installation of the seals.

This treatment is usually carried out on large quantities or batches, however, if you have any such needs, we recommend you contact us to enable us to analyse your request and propose the appropriate solution. We provide the following different types of treatment and surface coatings:

- PTFE

- Coloured PTFE

- Silicone

- Talc

- Micro Talc

- Molykote

- Graphite

- Chloride

- Rough

*Requesting and downloading the technical data sheets for each type of treatment is subject to the purchase of seals subjected to any of the aforementioned coatings.

PTFE

PTFE (polytetrafluoroethylene) coating, also known as TEFLON® (the registered trademark of Chemours), is a fluoropolymer-based coating designed to provide excellent anti-adherence to the seals.

PTFE is a material that is suitable for contact with food (FDA), and as such is used in many industrial sectors such as food, beverages, chemicals, textiles… The process for coating seals with PTFE Teflon® consists of four different stages:

- Degreasing – Consists of the removal of any organic or inorganic residue on the parts. The seals to be treated need to be degreased to do this.

- Sandblasting – The preparation of the surface to be coated in order to guarantee the maximum adherence of Teflon® by sandblasting with aluminum oxide.

- Application – This is conducted using liquid, electrostatic, HVLP spray guns or powder guns. The process can consist of several layers of product, depending on the purpose of the coating.

- Curing – The coating needs to be polymerised to ensure Teflon® retains all its properties. This involves keeping the seals at a temperature of 360 ºC for 10 minutes.

SILICONE

A silicone coating provides seals with greater anti-adherence, impermeability and mechanical resistance. In addition, silicone seals have better sealing and thermal insulation. A silicone seal has the following advantages:

- Greater thermal resistance.

- Good flammability properties.

- Excellent impermeability (even in hostile conditions: weather, water, steam, smoke and combustion gases).

- Excellent flexibility.

- Easy to clean.

- Greater durability.

MOLYCOTE

Molykote is the trade name for special Dow Corning lubricants. This lubricant is designed to deal with industrial lubrication issues and to reduce friction and wear.

Treating O-rings with Molykote, which features molybdenum disulfide (MoS2) in the lubricant, gives rise to an end product capable of withstanding high loads, high and low working temperatures, dirt and dust, aggressive chemical environments and extreme speeds.

The MoS2 is placed in the elastomer in the form of a dry lubricating film by deposition on the sealing surface. This produces a mechanical interlock, which reduces friction and wear caused by dynamic stress in the long term. The main advantages of this type of treatment are:

- It improves separation in automatic assembly.

- It reduces friction and dynamic stress.

- It controls contamination.

- It provides protection against corrosion.

- It dissipates heat.

- It transmits power.

- The process is suitable for all types of elastomers.

When used on O-rings, this static lubricant enables them to be used in advanced applications that require high electrical conduction, heat transfer, vacuum sealing and/or shear stability.

TALC

It is often necessary to improve the friction coefficient of O-rings, as they normally have rough and sticky surfaces. In these cases, surface treatments such as talc can be used. This method reduces friction, both to facilitate assembly and to prolong service life.

Treatment with talc consists of applying a powder coating to seals in a drum. No crosslinking with the elastomer surface occurs in this process.

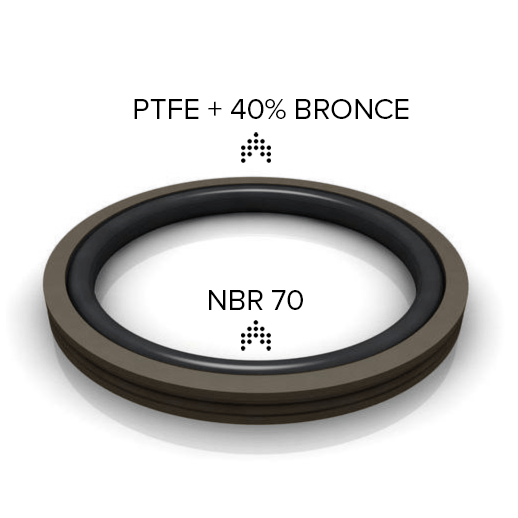

Silrings, JIOrings’ composite PTFE seals

When unity is strength

JIOrings composite seals (known as Silrings) are a combination of the best of three materials: PTFE, bronze and NBR.

And it is the benefits of each of the three materials that make them unique gaskets, both for use in dynamic and static applications.

What is PTFE?

Polytetrafluoroethylene (PTFE) is an industrial-use plastic with a molecular composition that provides it with unique characteristics different from polyethylene, the most common plastic in daily use.

Best known by its trade name, Teflon® (registered trademark of Chemours Company), it is composed of fluorine and carbon and is one of the most resistant plastics to extreme temperatures and exposure to different chemical agents.

In the case of Silrings, the PTFE is complemented with mineral filler, more specifically 40% bronze.

Seals made of this combination are recommended for heavy work due to their resistance to wear and their hardness. They are often used in the following applications:

- Pneumatic, hydraulic and mechanical parts

- Manufacture of bushings and bearings in mechanical equipment

- Hydraulic system components

- Track rollers in the textile industry

- Ball joints and swivel joints in the automotive industry

How does bronze filler enhance the PTFE?

Bronze (Cu) by definition is all copper and tin alloy, in which the former is the base and the latter features in a proportion of three to twenty per cent. The addition of 40% bronze to PTFE has several positive effects on Silrings:

- It increases hardness and compressive strength

- It increases resistance to wear

- It improves thermal conductivity

- It improves dimensional stability

- It reduces cold flow

What role does the NBR play in all this?

In the case of Silrings, NBR O-rings (acrylonitrile-butadiene rubber) provide sealing and resistance to:

- Oils and greases based on mineral oils

- Aliphatic hydrocarbons

- Vegetable and animal oils and fats

- Hydraulic oils (H, H-L, H-LP)

- Hydraulic fluids (HFA, HFB, HFC)

- Silicone oils and silicone greases

- Water (maximum 80 °C)

Check out our stock of Silrings at our online store:

What is the service life of an O-ring?

Gaskets also age

We need to differentiate between the time for which a gasket can or should remain in storage and its time of use, or in other words, its passive shelf life and active service life.

The service life of O-rings is governed by international aerospace regulation SAE AS5316, which defines all storage and service life conditions for elastomer products:

| Material | Service life |

| FKM | Unlimited |

| FVMQ | Unlimited |

| HNBR | 15 years |

| NBR | 15 years |

| FFKM | Unlimited |

| PTFE | Unlimited |

| VMQ | Unlimited |

We should not forget, however, that the information in this table is not binding. This information should be used simply as a basis on which to establish the requirements for the service life of gaskets, which will depend on the conditions to which they are subjected.

To ensure the longest possible service life of gaskets without them losing any performance with regard to what they are intended for (sealing properties), they must be stored properly, installed carefully and the conditions to which they are exposed must be known in order to conduct replacement or maintenance work when required.

The efficacy and duration of the sealing effect of O-rings are linked to the maintenance of their chemical and physical characteristics.

Tips for proper storage

Following a few basic storage tips will enable you to ensure your gaskets have a long service life.

- They should be stored at a temperature of between 15 °C and 38 °C.

- Relative humidity should be less than 75%.

- Gaskets should not be exposed to direct sunlight.

- They should not be exposed to sources of ionising radiation.

- They must not feature any kind of deformation and they must be tension-free.

Tips for installation

If you assemble a gasket incorrectly, this could cause superficial scratches that will undermine its sealing capacity and cause the mix to age prematurely.

The replacement of any gasket (in poor condition) entails shutting down the facility and often complex maintenance activity that needs to be scheduled in order to mitigate the economic impact thereof.

The integrity of a gasket may be compromised in the assembly or installation phase, hence the following should be taken into account:

- Avoid superficial damage: for which we recommend the use of lubricants or stretching the ring in order to widen the inner diameter.

- Avoid twisting the O-ring section: for which we recommend the use of Quad-Rings and their four support points, which are ideal for hydraulic, pneumatic and mechanical applications.

Depending on whether the installation is radial or axial, we will select a gasket with an inner diameter equal to or less than the diameter of the part to be sealed.

Check out our installation tips.

Once gaskets are in place, it is almost impossible to define their service life, as this will depend on all the factors involved: time of use, friction, temperature, fluids…, however proper installation and monitoring while they are active are important.

2021 is drawing to a close

It is said that we are animals of habit and, in this case, we can´t agree more. As the year draws to a close, we would like to share all the activities that have had a positive impact on our customers with you.

We continue to invest in quality

Quality is synonymous with trust. Over the years we have worked hard to have our seal compounds certified by independent entities and laboratories. International certification attesting to the fact that our seal compounds meet all the health, portability and safety requirements applicable to international markets is of paramount importance to you and, therefore, to us.

Increasing stock

When we say that we have one of the biggest stocks of O-Rings in the Iberian Peninsula, we are not exaggerating. With more than 45 million seals in stock, it is highly unlikely that we won´t have what you are looking for.

Moreover, this year we have created a new stock of composite seals (Silrings) and floating seals (Garseals), and these two product ranges are already immensely popular. We should also mention the considerable investment we have made in spools of extruded profiles in original materials (Perbunan®, Viton®, Xiametre®, Keltan®, Neoprene®). In addition to cord ring, we are becoming increasingly proficient in square extruded cord and quad-ring extruded cord.

We at JIOrings make every effort to keep our stock of the most popular seals up to date, in addition to those new to the market.

Committed to the environment

We are aware that natural resources are limited and that is why we at JIOrings continue to take measures to comply with the three Rs: reducing, reusing and recycling.

To this end, we have implemented a further measure this year and we have begun using biodegradable bags and recyclable adhesive tape and we have started delivering our gaskets in neutral brown boxes.

All this is to enable you to reuse our packaging material (bags) and shipping material (boxes). And in the event you are unable to reuse this material, you can recycle the entire boxes without having to remove the seal.

Consolidation and commitment

The family is growing. The company has had a total of 12 employees for a few years now, but in less than a month´s time there will be 14 of us and we are not superstitious.

Raquel Díaz Mencía joined our warehouse staff in December. After analysing the large volume of work, and in the hope that this trend will continue over the next few months, we decided we needed to expand our warehouse resources, as an additional pair of hands will help us to continue finding gaskets as quickly as possible.

Saioa Martín Jobajuria is due to join the company in January, and will help us strengthen the Purchasing and Logistics departments.

We hope these two new additions will help us to continue improving our performance and customer service.

Increasingly online

Our customers are the centre of our online activity.

The Internet is one of the best tools available for communicating with you. All the up-to-date information on sealing gaskets, product catalogues, technical documentation, standard measurement tables, certifications… in short, all the information required for purchase decision-making can be found at www.jiorings.com.

Furthermore, a single click will take you to our online store, where you will find one of the biggest stocks of seals available. We make things easy for you, enabling you to purchase while saving time and money from among more than 45 million seals online available in stocks that are updated in real time.

What´s more, we have been working hard this year to create a new online store in 2022, featuring a combination of information and the possibility of purchasing using a fast, intuitive and improved e-commerce system.

We hope to live up to your expectations!

Our best seals and best wishes for 2022!

We bid farewell to 2021 proud of everything we have achieved (this was the best ever year for JIOrings, and one in which we have broken all the records) and of what we can offer you in 2022:

• O-Rings (NBR, FPM, EDPM, VMQ, FFKM, ENCAPSULATED): 35 million

• Quad-Rings: 900,000

• V-Rings: 178,000

• BUR: 156,000

• U-Rings: 50,000

• Rotary Shaft Seals: 26,000

• Washers: 750,000

• Spools (o-ring, square profile, quad-ring profile): 3,000

• Silicone plugs or stoppers for barrels: 20,000

Have a look at our stock and prices and programme your orders.

We will say goodbye, as would be expected, by wishing you all the best for 2022.

O-Ring boxes: variety, order and quality

Do you know the advantages of seal boxes?

Boxes, cases or kits of sealing gaskets (comprised of O-Rings, X-Rings, Bonded-Seals, Cord-Ring, etc.) are an excellent option thanks to the great variety of sizes that they contain.

These seals boxes are perfect for industrial supplies, machinery repairers (TSS – Technical Support Service) and maintenance staff. The great variety of sizes is very useful when making urgent repairs.

However, in addition to professional use, O-Ring kits are very popular among DIY lovers, as they are ideal for home repairs.

Advantages of the boxes/cases

- Each case has an assortment of seals in many references.

- Its quality-variety-price ratio is very reasonable.

- Thanks to its presentation in a box with compartments, the seals will always be ordered by size and prevent them from becoming lost.

- Each case has a summary of all sizes and their units so that the customer can exhaustively control their consumption.

- The box can be replenished as the seals are used. Being standard measurements, at JIOrings we can send you the sizes you need replacing in 24 hours.

Consult the boxes available in stock

| On-line Store Reference | Description | |||||||

| BOXSP568IB70XBL | CORD RINGS Box Material/Shore: NBR70 Dimensions: 5 CUTTER + STRIP + GLUE |

|||||||

| BOX568TH70XGE | O-RINGS Box Material/Shore: HNBR70 12 Dimensions 200 Parts 1,78-2,62-3,53 |

|||||||

| BOX568IB70XBL | O-RINGS Box Material/Shore: NBR70 36 Dimensions 436 Parts 1,78-2,62-3,53 |

|||||||

| BOX574IB90XBL | BACKUP RINGS Box Material/Shore: NBR90 36 Dimensions 293 Parts |

|||||||

| BOX575AU92XBL | BACKUP RINGS Box Material: POLYURETHANE 24 Dimensions 475 Parts |

|||||||

| BOXBTS1IB90XBL | BOSS-TUBE FITTINGS O-Rings Box Material/Shore: NBR90 9 Dimensions 72 Parts |

|||||||

| BOXBTS2IB90XBL | BOSS-TUBE FITTINGS O-Rings Box Material/Shore: NBR90 4 Dimensions 32 Parts |

|||||||

| BOXCAP | PLUG KIT 24 Dimensions 553 Parts Plastic plugs |

|||||||

| BOXQRIB70XBL | KIT X-RING Material/Shore: NBR70 36 Dimensions 226 Parts 1,78-2,62-3,53 |

|||||||

| BOXMAXIAGRI | MAXIAGRI Box 1.525 Parts O-Rings NBR70 + BONDED SEALS + SAE |

|||||||

| BOXMAXIPLANT | MAXIPLANT Box 1.455 Parts O-RINGS NBR90 + METALBUNA + SAE + GREASE FITTING |

|||||||

| BOXBSABSP | BONDED SEALS Box 7 Dimensions 114 Parts BSP Self-centering |

|||||||

| BOXBSAMET | BONDED SEALS Box 7 Dimensions 125 Parts Metrics Self-centering |

|||||||

Hydraulic U-Rings and their versatility

Hydraulic U-rings are also known as lip seals

Among the wide variety of existing sealing gaskets, there is a type of seal that stands out above the rest thanks to its versatility: hydraulic U-Rings. Consult our stock of lip seals in real time, without obligation:

| U-Ring | Profile | Material | Hardness | Check stock |

| UN |  |

Polyurethane | 90 SH A | |

| D2 |  |

Polyurethane | 95 SH A | |

| D3 |  |

Polyurethane | 95 SH A |

What characteristic makes the U-Rings so special?

The answer is simple, and we have already revealed it to you: their versatility.

The great symmetry of the U-Ring provides a very effective closure, and due to the self-compression of the lips during the assembly process and the effect of the opening of the lips due to the pressure received, this achieves a great seal. The UN U-Ring (also known as the symmetrical or equal lip seal) can be mounted both on the rod and on the piston and, on the other hand, it can be used on both single-acting and double-acting cylinders.

The D2 and D3 U-Rings, on the other hand, are only valid for the rod because the outer lip is higher than the inner lip. The PUL95 blend for the UN and PUL93 blend for the D2 and D3 guarantee a high-performance polyurethane (PUR and PU) in all hydraulic and/or pneumatic applications.

If to all of this we add that they also have a low cost, are easy to assemble and disassemble, and have an excellent resistance to wear, it is not surprising that hydraulic U-Rings are the ultimate versatile seal.

Mostly manufactured in L-93 polyurethane, a high-performance thermoplastic, hydraulic U-Rings offer an excellent resistance to abrasion, friction and wear, as well as a low permanent deformation.

At JIOrings, we have the widest range of UN measurements on the market, with around 1,500 standard measurements both in metrics and inches, which allows us to immediately respond to the market needs without having to offer machined parts that are usually more expensive. We also have a special case with 4 U-ring mounting clips.

Remember that whenever you need to place an order for U-Rings, you have the guarantee that you will receive it within 24 hours if you are in Spain and Portugal. We are the quickest way to find a seal and, in the case of U-Rings, their versatility is more than ensured.

O-Rings for all four elements

Discover some applications of the sealing gaskets

Our seals are prepared to give their best in the 4 elements of nature (water, fire, earth and air), their main function being to ensure fluid tightness between the union of two surfaces, for example, in hydraulic cylinders and pneumatic cylinders. But the reality is that we can find them in an infinite number of “scenarios” related to the 4 elements:

W A T E R

- O-rings for drinking water with specific approvals (ACS CLP, 3A, EN681, KTW-UBA, KIWA, NSF61, WRAS, W270, W534)

- O-rings for various water treatments such as filtration, purification, desalination, irrigation, pumping…

- O-rings for oceanographic buoys.

- O-rings (green FPM) for marine engines.

- O-rings for diving equipment (TW-UBA, KIWA, NSF61, WRAS, W270, W534).

F I R E

- Seals for high temperatures and flame retardant seals with specific approvals (UL)

- O-rings for fire extinguisher pressure gauges.

E A R T H

- O-rings and X-Rings for agricultural machinery that prevent dirt from entering the shafts.

- ME2 scrapers for public works machinery.

- O-rings for fastening mining masonry.

A I R

- Special EPDM O-rings for oxygen for ventilators in hospitals.

- Gaskets to create a seal on a surface that carries gas with specific approvals (EN549/EN682).

- O-rings for compressed air rifles.

FKM/FPM/Viton®, three names for the same rubber

Do you know what Viton® is?

Viton® is a trademark of a synthetic rubber and fluoropolymer elastomer commonly used in the manufacture of O-Rings. The name is a trademark registered by The Chemours Company and its international abbreviation is FPM (DIN/ISO denomination) or FKM (ASTM). It is also known as Fluoro-Elastomer or by its trade name, Viton.

The Viton® brand is by far the most recognised FPM/FKM brand worldwide, to such an extent that, in the industrial world, the word has undergone a lexicalisation process. In other words, like the word Kleenex® designates a tissue, the word Viton® is used to refer to gaskets manufactured in FPM regardless of their raw material. The truth is that, since its invention by DuPont™ (now The Chemours Company), many other chemical companies have developed their own FKM. We can cite Dyneon®, DaiEl ®, Fluorel®, Noxtite® and Tecnoflon®, among others.

DuPont, an American multinational company, is one of the largest chemical companies in the world. As well as having developed Viton, it is also the creator of other well-known materials such as Neoprene®, Nylon®, Lycra®, Plexiglass®, Teflon®, among others. Because it always trademarks its progress, many of its products are even more famous than the company itself.

Why do our customers choose the Viton® O-rings?

Basically, because their thermal resistance is the best, no other elastomer can compare.

Viton® is a hexafluoropropylene thermopolymer, with vinylidene fluoride, tetrafluoroethylene and methylvinyl etherperfluoro. On the one hand, the energy of the carbon-fluorine bond is much greater than that of the carbon-hydrogen bond and also greater than that of the carbon-chlorine bond. On the other hand, the much larger fluorine atoms exert a shielding effect, which protects the main carbon chain. Hence its thermal resistance.

The resistance to continuous temperature is +205 ºC without losing its mechanical properties. In intermittent, it can reach up to 220°C. Some “improved” compounds like our “OZM410-121294” blend resists temperatures of up to +250ºC.

Stock of O-rings in Viton®

At JIOrings, we have an extensive stock of Viton gaskets and the possibility to manufacture in this material or schedule their manufacture. As well as O-Rings, we also have quad-rings, V-Rings, cord-rings and seals (in high demand) in Viton.

Did you know that...?

The surname “Vitón” is quite common in Spain and comes from the Latin “vita”. Apparently, it appears 234 times as a first surname and 206 times as a second surname. Nobody has it as both surnames. It is also a surname that appears in the Sephardic community of Morocco.

What is Shore A Hardness?

Because hardness matters too...

This is one of the most used scales for measuring the hardness of elastomers. Although it is not the only one, apart from scale A there are scales B, C, D, 0 and 00. Of these, the Shore D scale is also used to measure the hardness of harder elastomers.

The hardness of an elastomer represents its stiffness against moderate stress, such as those that it frequently subjected to in an application.

There are two methods for obtaining the hardness of O-rings and other seals:

Durometer

A durometer is an instrument with a frusto-conical tip that, on penetrating the elastomer, produces a reaction in the calibrated metal spring. When the Shore A durometer indicates readings of greater than 90°, the use of the Shore D durometer, which has a tapered tip and a stiffer spring, is recommended.

To ensure the correct use of this measurement tool, we at JIOrings recommend:

• Using the durometer on a flat, clean, polished surface.

• Measuring perpendicular to the durometer´s indenting foot.

• Repeating the test 3 times in a different place on the part/seal each time.

Due to its simplicity and convenience, the Shore hardness form of measurement is widely used as a production control. The use of IRHD hardness is recommended for the purpose of more exact classification or specification:

Macro IRHD

This durometer is designed to obtain hardness in all types of elastomers and plastics with a minimum thickness of 6 mm. The system consists of a stand with a testing table and a macro head designed to accommodate IRHD N, IRHD L, IRHD H and Shore inserts. The inserts feature 1, 2.5 and 5 mm diameter ball indenter and test loads from 2.65 to 5.70 N.

Micro IRHD

A micro durometer is used to obtain hardness in all types of elastomers and plastics with a maximum thickness of 5 mm. The system consists of a stand with a testing table and a micro head with a 0.395 mm diameter ball indenter and test loads from 8.3 mN to 153.3 mN. The measurement stroke is 0.3 mm and the range is between 30 and 100 micro IRHD.

Hardness equivalence table

| Shore A | IRHD | Shore D | Shore 0 | Shore 00 |

| DIN 53505 | ASTM D 1415 | DIN 53505 | ASTM D 2240 | ASTM D 2240 |

| Compact and cellular elastomers | Compact elastomers | Polyurethanes, rigid PTFE, thermoplastics and very hard elastomers |

Medium density compact and cellular elastomers | Medium and low density cellular elastomers |

| 100 | 100 | 58 | ||

| 95 | 95 | 46 | ||

| 90 | 90 | 39 | ||

| 85 | 85 | 33 | ||

| 80 | 80 | 29 | 84 | 98 |

| 75 | 74 | 25 | 79 | 97 |

| 70 | 68 | 22 | 75 | 95 |

| 65 | 64 | 19 | 72 | 94 |

| 60 | 62 | 16 | 69 | 93 |

| 55 | 54 | 14 | 65 | 91 |

| 50 | 49 | 12 | 61 | 90 |

| 45 | 44 | 10 | 57 | 88 |

| 40 | 39 | 8 | 53 | 86 |

| 35 | 35 | 7 | 48 | 83 |

| 30 | 28 | 6 | 42 | 80 |

| 25 | 35 | 76 | ||

| 20 | 28 | 70 | ||

| 15 | 21 | 62 | ||

| 10 | 14 | 55 | ||

| 5 | 8 | 45 |

What´s on the way…

To the JIOrings warehouse – We continue to expand our stock

We started the year with a stock of more than 40 million O-rings, almost 1 million quad-rings, 200,000 V-rings, 175,000 anti-extrusion rings (BUR), 125,000 bonded seals, 60,000 U-rings, 40,000 rotary shaft seals, 20,000 wiper seals, 23,000 axial seals, 2,150 spools of cord-ring … And for 2020, in accordance with the increase in numbers of orders this financial year, we will strive to increase our stock of FPM-Viton® seals and spools of cord-ring in different thicknesses and materials. Moreover, we will begin marketing special seals for the healthcare sector, which will comply with all the requirements of such a demanding sector.

We ended 2019 with an increase in the sale of silicone plugs for wine barrels and the first plugs for whisky barrels, and we intend to continue increasing the sales of both these models. We have made excellent progress with regard to the marketing of Nortap® plugs in the French market this year and we hope to close deals with new customers in countries including Italy, Austria and Hungary, while not forgetting the domestic market.

Our workforce – Consolidation and commitment

We celebrated our 15th anniversary in 2019, and although we haven´t held any special celebrations for our “Crystal Wedding”, we always meet up on the Friday of each anniversary, for the activities associated with the annual river Sella race and at the meals organized both by our personnel and the company´s annual get-together.

We have three partners and nine employees, and it´s everyone’s job to ensure we´re the fastest way of finding a seal. Jean-Albert Morlard, Iñigo Barrenetxea and Óscar Zamorano define the annual goals and run the company; César Garretas and Iñaki Bilbao are in charge of domestic and international sales respectively; Maite Jiménez is the head of the administrative department and Silbia González the head of the marketing department; and Fernando Sánchez, Juanra Laderas, Laura Domínguez, Gonzalo Pardo and Unai Pereda work hard in the warehouse from Monday to Friday to ensure all orders are delivered on time.

Our commitment is to continue working and training to go on providing a quality service that complements our quality products.

Those of you that know us are aware that our company is increasingly committed to our workers and the environment. And I say “increasingly” due to the fact that we know that part of our workers’ well-being is in our hands, and we at JIOrings do everything possible to ensure the hours spent here at work are healthy ones. As for the environment, we will continue to comply with the three Rs (Reduce, Reuse, Recycle) as a means of achieving a minimal impact.

Sponsorships – values and sport

We have two new signings for the JIOrings Running Team in 2020 and we are preparing a powerful schedule for both running and cycling. It will be difficult to surpass Isaak Rosillo‘s enduro adventure in Nepal, but knowing him, he´s probably already planning his next feat. We will have to wait to find out where the traditional and floral JIOrings kits that have brought us so much success this year will be displayed. Moreover, we are extremely happy due to having resumed our collaboration with Galdakao Bolei Taldea in the 2020 season.

JIOrings – Online and offline improvements

Next year we will have our new plant and its forklift in operation. This third storage plant will enable us to continue expanding our stock of both seals and plugs. Regarding this line, we will try to go ahead with our automated warehouse project, with the aim of improving the time spent preparing the lines.

In relation to offline operations, we will continue to improve both with regard to accounting (the implementation of automated accounting banking consolidation), the environment (we will continue with the integrated recycling process), operations (improvement in the advanced technical data sheet to enable us to search for seals by colour, approvals, characteristics, etc. .), and quality (continue to approve our own mixtures) …

And if that wasn´t enough, in relation to online operations we hope to publish the new JIOrings website in January, featuring an updated design, far more intuition and, above all, fast. Although I don´t think that´s the only surprise, because we will be working on our online store in 2020, with the same objective, improving the browsing and usability of the store, creating a simple purchasing process, displaying the most popular products in order to facilitate shopping, improving product photos in detail …

Another year of improvements awaits us!